Graphene aluminum ion batteries with ultra-fast charging

The “graphene revolution” is almost here. Australian scientists specializing in aluminum-ion batteries are now working with Brisbane-based Graphene Manufacturing Group to commercialize a technology that could transform energy storage.

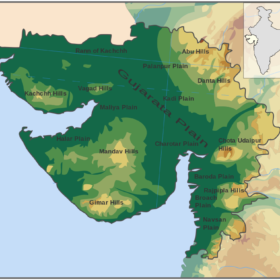

US-based EverGreen Power to assess feasibility of 300MW wind-solar-storage project in Gujarat

The U.S. Trade and Development Agency (USTDA) is funding the 300MW wind-solar-storage project as part of its mission to promote sustainable infrastructure projects in partner countries like India.

The long read: Battery testing builds certainty

Owners and operators of energy storage systems, as well as investors, need transparent ways to evaluate battery performance. They need certainty that the selected batteries for their ESS projects will perform reliably, have predictable life expectancies, and meet projected revenue and contractual obligations over their lifetimes. The economic viability of entire projects depend on this confidence, writes Michael Kleinberg of DNV.

India gets first community energy storage connected to grid

Tata Power Delhi Distribution Limited has installed a 150 kW/528 kWh battery energy storage system at Ranibagh Substation in New Delhi. The system will support the utility in managing the peak load, voltage regulation, power factor improvement, frequency regulation, and deviation settlement mechanism at the substation level. Besides, it will provide a power backup of 150 kW for 4 hours duration to preferential consumers in case of a grid outage.

‘Solar could supply half of a new 600 GW clean energy ambition’

U.S.-based researchers have modeled the costs of achieving 200 GW, 400 GW and 600 GW of renewables capacity in India this decade and concluded PV should supply no more than half of the generation facilities and policymakers should shift their focus to wind power.

Could India establish itself as the global leader in energy storage?

In India, the lack of suitable fiscal incentives and relevant experience, combined with high upfront capital costs, has hindered the adoption of battery energy storage systems (BESS) in comparison to other developed countries. However, there is potential for the country to take the lead.

Haryana plans 93 MW solar power capacity

The Haryana Power Generation Corporation Limited (HPGCL) plans to develop 77 MW solar capacity on its own land and 16 MW on land owned by village councils.

The long read: Nickel and dime batteries to LFP

Lithium-ion phosphate batteries are making a comeback. Thanks to high nickel prices and limited feedstock supply, the EV industry is driving this change. There is no need to fret about the onset of slightly lower energy density, though, as this development has some benefits for the stationary storage market.

Australian firm launches 36 kW/120 kWh storage system made of second-life EV batteries

Relectrify said its new storage system is suitable for commercial and industrial applications and is designed for installations in the 120 kWh to 2 MWh range.

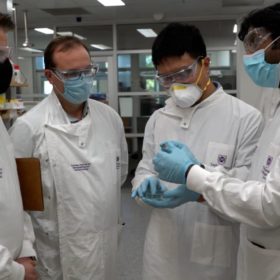

The long read: A new era for battery materials

Every year, chemical and energy companies produce $15 billion worth of commodities such as carbon black, silicon oxide, and aluminum oxide, for manufacturing purposes. Engineers do this by pumping chemicals into a flame and collecting material formed in the fire, in an approach known as flame spray pyrolysis. This approach, according to scientists at Argonne National Laboratory, has the potential to create more advanced materials for use in next-generation storage batteries.