The Hydrogen Stream: EU backs €400 million H2 scheme in Spain

The European Commission has cleared a €400 million ($455.2 million) Spanish aid program to scale renewable hydrogen output, backing up to 345 MW of electrolyzer capacity and targeting 221,000 tons of production via the EU Hydrogen Bank’s 2025 auction round.

Honeywell unveils AI-assisted suite to optimize green hydrogen plants

Honeywell Protonium uses machine learning to optimize the design and operation of green hydrogen projects. Aternium, a US-based large-scale clean hydrogen producer, will deploy the technology at its planned Mid-Atlantic Clean Hydrogen Hub.

The Hydrogen Stream: L&T sets up green hydrogen arm

L&T Energy Green Tech has incorporated a wholly owned subsidiary, L&T Green Energy Kandla Pvt Ltd (LTGEK), for development of green hydrogen and its derivative (including green ammonia) projects and to carry out other related business activities.

The Hydrogen Stream: Chile selects electrolyzer companies for local assembly

Chile’s economic development agency Corfo has selected three companies – two Chinese and one Spanish – to build electrolyzer production facilities in the country. The projects, set to begin operations by mid-2026, will assemble alkaline and proton exchange membrane (PEM) electrolyzers ranging from 50 kW to 5 MW.

The Hydrogen Stream: BPCL collaborates with BluJ Aerospace, ANERT, and CIAL for world’s first hydrogen-powered VTOL aviation ecosystem

Bharat Petroleum Corp Ltd (BPCL) will establish hydrogen refuelling infrastructure for the hydrogen-fueled vertical take-off and landing (VTOL) aircraft developed by BluJ Aerospace. It will also design and develop an indigenous proton exchange membrane (PEM) hydrogen fuel cell with high power density to facilitate vertical lift-off.

The Hydrogen Stream: TotalEnergies to buy green hydrogen from RWE

The Hydrogen Stream: TotalEnergies to buy green hydrogen from RWE

TotalEnergies says it has signed a 15-year deal with RWE to buy 30,000 tons of green hydrogen per year from a 300 MW electrolyzer in Germany, while Plug Power has announced a partnership with Southwire to create a clean hydrogen ecosystem in Texas.

The Hydrogen Stream: BGR Tech partners alkaline electrolyzer manufacturer Stargate for green hydrogen projects in India

BGR Tech will integrate Stargate’s alkaline electrolyser stacks with its in-house developed balance-of-plant to execute green hydrogen production projects in India.

The Hydrogen Stream: India begins trials of hydrogen trucks for long-haul transportation

The trial marks a significant step forward in assessing the real-world commercial viability of using hydrogen powered vehicles for long-distance haulage as well as setting up the requisite enabling infrastructure for their seamless operation.

The Hydrogen Stream: US researchers link H2 impact to production

US researchers say hydrogen’s climate impact depends primarily on production methods and feedstock emissions, while Nikola Corp. has recalled 95 hydrogen-powered trucks and filed for Chapter 11 bankruptcy.

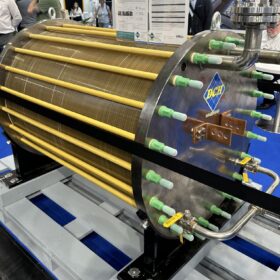

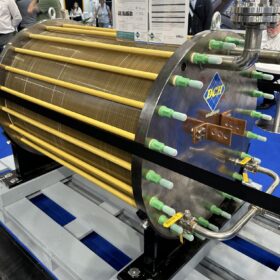

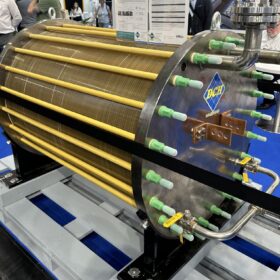

The Hydrogen Stream: BGR Tech partners Korea’s Elchemtech for PEM water electrolyser technology in India

BGR Tech Ltd has signed a Memorandum of Understanding to introduce Elchemtech’s advanced proton exchange membrane water electrolyser in India. BGR Tech will integrate these electrolysers in its balance-of-plant (BoP) for green hydrogen projects in India.