India may fall behind its 2030 EV sales forecast

A new report says India will have only 50 million electric vehicles (EVs) on road by 2030 despite a ramp-up in domestic manufacturing, falling behind by 40% on the cumulative sales projections by NITI Aayog. It also recommends policy measures to improve India’s chances of realizing 80 million EV sales by 2030.

India will have 125 GWh of lithium batteries ready for recycling by 2030

India will see a cumulative demand for around 600 GWh of lithium-ion batteries from 2021 to 2030 across all segments. The recycling volume coming from the deployment of these batteries will be 125 GWh by 2030.

Ola to open battery cell R&D center next month

The electric mobility company will open its battery innovation center (BIC) in Bengaluru next month as it looks to build indigenous cell technology and manufacture Li-ion cells in India at scale.

Sanvaru plans new lithium battery plant as orders exceed capacity

Haryana-based Sanvaru is expanding its lithium battery production capacity to 400 MWh per year by setting up a new factory in Haridwar.

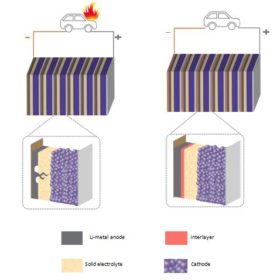

Indian researchers find way to stop dendrites in solid-state lithium batteries

Researchers from the Indian Institute of Science, Bangalore, have found that nanoscopic refractory metal layers like tungsten could improve dendrite growth tolerance in electrolytes of solid-state Li-ion batteries. The team collaborated with researchers from Carnegie Mellon University.

US startup unveils non-flammable batteries for EVs, storage

Alsym will produce its new batteries – made of readily available materials, without lithium or cobalt – for electric vehicles, stationary storage, and marine applications.

Used Audi e-tron batteries to power rickshaws in India

Battery startup Nunam is working with German carmaker Audi AG and the Audi Environmental Foundation to roll out electric rickshaws powered by used Audi e-tron used batteries. It expects to launch the e-rickshaws in India at some point early next year.

Nexcharge’s 1.5 GWh factory to make at least 150 storage products

Nexcharge will manufacture lithium energy storage products for electric vehicles and grid-based applications at its newly opened plant in Gujarat.

Bhago Mobility acquires stake in lithium battery supplier Pastiche

Bhago Mobility Solutions, the green energy vertical of automotive parts manufacturer Modern Automotive, will invest $16 million in a partnership with Pastiche. They plan to jointly develop solid-state and lithium-ion batteries for electric mobility and energy storage.

Ola Electric invests in Israeli EV battery specialist StoreDot

The Indian electric mobility player, which plans gigawatt-scale battery cell manufacturing, has embraced Israel-based StoreDot’s extreme-fast battery technology that charges from 0 to 100% in just five minutes.