Waaree lithium batteries run electric forklifts at Chennai airport

The energy storage system arm of Waaree Group has designed and developed Lithium batteries to power ACE Ltd’s electric forklifts running at Chennai airport.

Electric vehicle transition presents US$266-billion investment opportunity this decade

A new report by government thinktank NITI Aayog and Rocky Mountain Institute (RMI) identifies financing as one of the hurdles for India’s electric mobility transition. It proposes solutions to lower the cost and increase finance for electric vehicles in the nation.

Battery startup Gegadyne Energy raises INR 33.4 crore from V-Guard

The Mumbai-based battery startup develops advanced nano-material composites to enable quick-charging batteries for electric vehicle (EV), industrial storage, and consumer electronics space.

India’s 2030 electric vehicle ambition could create INR 85,900-crore battery opportunity

A new report says that the nation would require an estimated annual battery capacity of 158 GWh to realize its 2030 electric vehicle (EV) adoption target. Meeting this potential demand would require investments exceeding INR 85,900 crore (US$ 12.3 billion) in case battery manufacturing is 100% indigenized.

Inverted Energy opens 100 MWh lithium battery plant

The lithium battery assembly facility at Okhla, New Delhi, would initially produce batteries for energy storage in residential, commercial and industrial sectors, and for electric mobility applications. The plan is to eventually cater to critical applications like telecom and healthcare as well.

C-MET seeks co-funding partner for lithium and sodium-ion battery cell manufacturing

The selected party will provide funding support of Rs 4 crore by way of design and development of machinery for lithium- and sodium-ion battery cell manufacturing. September 30 is the deadline to submit the interest.

India can become electric vehicle manufacturing hub within five years: Nitin Gadkari

The industry needs to cut a dependence on electric vehicle battery imports from China, according to the road transport minister, who said the government is looking to support research into alternatives to lithium-ion technology.

The long read: Cheaper, safer EV batteries to bolster grid

Electric vehicles can transition from liabilities to assets if steps are taken by battery manufacturers, the auto industry, and policymakers, argues Milan Rosina, a principal analyst in the power electronics and batteries division of Yole Développement.

UK based Faradion to start sodium-ion battery manufacturing in India

The sodium-ion battery technology developer has bagged its first order from ICM Australia and is looking at India as the next destination for manufacturing with the initial target set as 1 GWh.

Covid-19 impact on India’s energy storage industry

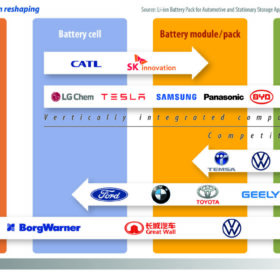

The onset of Covid-19 has brought into focus the critical importance of indigenization and localization of battery cells as a series of disruptions in the supply chain for Li-ion batteries will also affect Indian electric vehicles and stationary energy storage market.