IIT Kanpur, UK’s H.E.L to collaborate on battery testing

UK-based H.E.L Group will provide IIT Kanpur with the latest battery testing technology under a collaboration agreement signed with IIT Kanpur.

Exide Energy secured $85.3 million of orders for lithium-ion battery packs, modules in fiscal 2022-23

Exide Energy (Nexcharge), which started commercial production last year, received a healthy order inflow for lithium-ion-based battery packs and modules during FY 2022-23.

Sodium-ion battery fleet to grow to 10 GWh by 2025

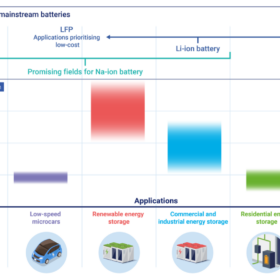

Global demand for sodium-ion batteries is expected to grow to just under 70 GWh in 2033, from 10 GWh in 2025, at a compound annual growth rate (CAGR) of 27%, according to UK-based market research company IDTechEx.

Sodium-ion vs lithium-ion batteries

Lithium-ion batteries remain the preferred choice for electric mobility applications in India due to their higher energy density, well-established infrastructure, and safety record. However, the development of sodium-ion batteries continues, and they may have potential advantages in terms of cost and environmental impact, making them a promising alternative in the future.

Epsilon Advanced Materials plans $650 million EV battery anode facility in USA

India’s Epsilon Advanced Materials will invest $650 million to set up a graphite anode processing facility in the USA. The facility will produce high-capacity synthetic anode materials for electric vehicle (EV) batteries.

Global sodium-ion battery market expected to reach $2.6 billion by 2028

The global sodium-ion battery market will grow at 16.2% annually to touch $2.6 billion by 2028. Major drivers include an increasing demand for these batteries as a lithium battery replacement for renewable energy storage and the growing trend towards low-speed electric cars.

GERMI develops biodegradable paper supercapacitor from seaweed

The researchers deposited reduced graphene oxide (rGO) and zinc oxide (ZnO) nanowires over seaweed cellulose to make the anode material for the supercapacitor. The device exhibited a greater energy density of 5.21 Wh/kg, a series resistance of 2.16 ohms, and no air degradation even after 5,000 cycles.

Lohum introduces 5 kWh storage system made of second-life EV battery

Noida-headquartered Lohum has introduced a 5 kWh energy storage system under its collaboration with MG Motor India to develop second-life solutions for used EV batteries.

Himadri invests US$6.7 million in Australia’s Sicona Battery Technologies

India’s Himadri Speciality Chemical has acquired a 12.79% stake in Sicona Battery Technologies, an Australian startup that specializes in high-capacity silicon anode technology for lithium-ion batteries.

Annual EV sales in India surpassed 1.2 million in FY 2023

Uttar Pradesh led the yearly electric vehicle sales with a 15.15% share of the cumulative 1.2 million units sold in FY 2022-23. It was followed by Maharashtra (12.72%) and Karnataka (9.14%).