BC Jindal Group announces INR 15,000-crore investment in solar and battery manufacturing

The BC Jindal Group has unveiled plans to invest INR 15,000 crore by 2030 to establish multigigawatt-scale manufacturing capacities for solar cells and modules, battery cells and packs, and solar glass.

Optimizing residential PV-driven heat pumps with lithium-ion batteries reduces LCOE by 7%

Scientists in Spain have simulated the combination of power-to-heat-to-power storage systems with lithium-ion batteries to supply energy needs and heat pump production of an electrified dwelling. PV self-consumption was found to increase by up to 20% and levelized cost of energy decrease by 7%.

Lithium-ion battery recycling plant comes online in Arizona

The opening of Ecobat’s new facility is just one of many indicators that U.S. battery recycling is on the rise.

Transforming discarded batteries into valuable resources

Rather than viewing battery recycling as waste management, it should be reframed as an economic and industrial opportunity. Advanced recycling techniques can recover up to 95% of lithium, cobalt, and nickel, reducing India’s reliance on raw material imports.

Challenges and opportunities for lithium-ion battery recycling in India

A new study examines the current status of lithium-ion battery consumption, and challenges and opportunities in the Indian recycling landscape.

Epic Energy enters licensing agreement with C-MET for lithium battery recycling

Epic Energy has entered a ten-year licensing agreement with the Centre for Materials for Electronics Technology (C-MET) for recycling of end-of-life lithium batteries (excluding lithium ferro phosphate batteries) using a hydrometallurgical process.

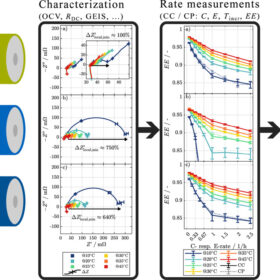

Sodium-ion vs. lithium-iron-phosphate batteries

Researchers in Germany have compared the electrical behaviour of sodium-ion batteries with that of lithium-iron-phosphate batteries under varying temperatures and state-of-charges. Their work shows how state-of-charge during cycling significantly affects the efficiency of sodium-ion devices.

Reliance Industries awarded 10 GWh advanced chemistry battery capacity under PLI Scheme

India’s Ministry of Heavy Industries has signed a programme agreement with Reliance New Energy Battery Ltd for 10 GWh capacity under the production-linked incentives (PLI) Scheme for advanced chemistry cells.

Epsilon Group commits INR 15,350 crore for EV battery materials, testing facility in Karnataka

Epsilon Group plans to invest INR 9,000 crore to set up a graphite anode manufacturing plant and INR 6,000 crore for a lithium iron phosphate (LFP) cathode manufacturing plant in Karnataka. In addition, it will invest INR 350 crore to build a battery materials and battery testing R&D and training center in the state.

Union Budget 2025-26: India focuses on waste-to-wealth to secure lithium battery supply chain

Finance minister Nirmala Sitharaman has submitted Union Budget 2025-26, which proposes customs duty exemption for waste and scrap of lithium-ion batteries and critical minerals.