India’s future energy options all add up to coal, agree the experts

Panellists including a government representative and a member of the chief policy thinktank used by Narendra Modi agreed coal will continue as the staple source of Indian power into the mid century and technology should be employed to ‘clean’ it.

India’s lithium-ion battery imports increase fourfold in two years

China, Hong Kong and Vietnam are the top three nations exporting batteries to India. Chinese imports were worth $773 million in the last fiscal year with Hong Kong shipping $267 million worth and Vietnam $114 million, according to the Ministry of Commerce.

EVs could become cheaper than combustion vehicles within three years: NITI Aayog CEO

A 50% fall in the price of Lithium-ion battery packs—to $76/KWh from $156/KWh today—will make the capital cost of electric vehicles lower than combustion vehicles. However, to realise the full benefits of EVs, it is important to charge them with clean power and not fossil power.

Li-ion Gigafactories: Niti Aayog seeks cabinet nod for Rs 7 billion annual subsidy proposal

Already approved by the finance ministry, the proposal aims to woo investors into setting up manufacturing units in India and lower battery costs with indigenization of technology. An aggregate manufacturing capacity of 50 GWh is planned to be set up over a period of 10 years, which would require investments worth Rs 355 billion.

Energy Storage: Top 5 Li-ion battery trends to watch out for

The Internet of Things, cloud analytics and artificial intelligence will find their way into battery management too, enabling OEMs to precisely measure and improve the life of their deployed assets. Lower battery costs and increased adoption in high-power commercial electric vehicles and grid support are the other trends shaping the market.

Pinnacle and China’s Phylion launch lithium-ion battery assembly unit in Maharashtra

Madhya Pradesh based Pinnacle Industries–a commercial vehicle components manufacturer–plans to roll out electric vehicle battery packs with Phylion cells and semi-knocked-down kits.

AEPPL to invest Rs37.15 billion in second phase of lithium battery plant

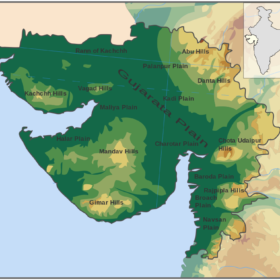

The joint venture between Japanese majors Toshiba, Denso and Suzuki will make the investment in the Gujarat plant over the 2021-25 period, having pumped Rs12.5 billion into the first phase of development.

UK University to help design EV batteries for Indian climate

The university researchers will provide expertise in the operation and management of lithium-ion batteries, environmental test facilities for battery modules and advanced battery analysis techniques.

“Our LFP battery technology is ideal for the Indian market”: SimpliPhi Power CEO

California-based SimpliPhi Power, which designs and manufactures lithium ferro phosphate (LFP) energy storage systems, has brought off-grid power to everything from the giant moon on Conan O’Brien’s talk show set to U.S. troops in Afghanistan and Iraq, to rooftops for Whole Foods and Airbnb. As the company prepares to enter into India, CEO and President Catherine Von Burg tells pv magazine why their LFP technology is best suited for India and their plans for the country.

India’s electric vehicle market will grow annually at 36% till 2026: IESA

Electric vehicle (EV) battery market will grow annually at 30%, growing almost six times to 28 GWh from 4.75 GWh in 2018. The EV infrastructure will grow at double the pace (60% annually), reaching 50,000 units from less than a thousand in 2018.