The long read: Does ALD live up to assembly line expectations?

As demand for atomic layer deposition equipment spreads among Chinese solar cell manufacturers, experts throughout the industry are sharing their insight on the merits of this emerging manufacturing technology. The numbers they crunch reveal tough competition for incumbent plasma-based deposition techniques. But beyond the hype, does atomic layer deposition truly offer the better deal?

Commercial solar at grid parity in China but a hard line is needed on soft costs

Deploying commercial and industrial PV in China without subsidy is already profitable in some areas, according to a new study, but prohibitive soft costs and cheap electricity are the main barriers for such installations in areas where grid parity remains out of reach.

Thinktank says India must prioritize a vertically integrated solar supply chain

To develop cost-competitive solar modules the nation must adopt a phased program and set up 15 GW of silicon-ingot-to-solar-module manufacturing capacity by 2024, according to The Energy and Resources Institute.

India to hike import tariff on solar equipment: Power minister

Tariffs will be hiked down the value chain in order to encourage domestic solar manufacturing, which currently stands at just 3.2 GW for solar cells and 8.5 GW for solar modules.

The long read: Change to the cast

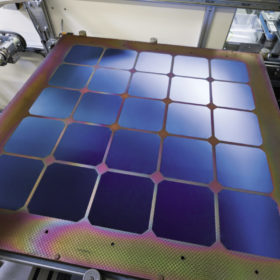

Few in the industry predicted the speed at which monocrystalline technology would develop, or the impressive cost reductions it would achieve by 2019. This has left producers of multicrystalline products facing rapidly shrinking market share and struggling to compete on a cost per watt basis. Many are now turning to cast mono processes, essentially creating a monocrystalline, or ‘mono-like’ silicon ingot in a multicrystalline furnace, to reach higher efficiencies and extend equipment lifetimes.

SECI tenders 1.5 GW solar with VGF support for state-run power generators

Micro and mini grid-connected projects will also be considered. The projects—to be developed on ‘build-own-operate’ basis—can be set up anywhere in India for self-use or use by government entities at maximum fixed tariffs of Rs 3.50/kWh. Bidding will close on August 23.

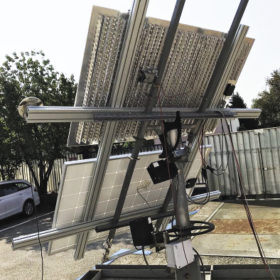

The long read: The importance of staying cool

“Solar cells prefer to operate in a refrigerator,” says UNSW Professor Martin Green. His global research team is now identifying viable ways to cool down solar PV modules while amping up energy production to an unprecedented level.

QMC bags fresh Amtronics order for solar cell production equipment

The $500k order follows the delivery of two high-volume quantum-dot production systems—valued at $1 million—to support roll-to-roll printing of thin-film solar cells at Assam facility.

Anti-dumping duty on coated steel will raise solar project costs by 2-4%: Care Ratings

India’s Directorate General of Trade Remedies (DGTR) has determined that flat steel products coated with aluminium and zinc are being dumped by manufacturers in China at dumping margins of 30-50%, South Korea (20-30%) and Vietnam (10-20%). It has proposed anti-dumping duty based on the same to offset material injury to domestic manufacturers.

CEL tenders 36,500 quantities of 75 W solar modules

Bids are invited for supply of 75 Wp solar modules based on crystalline silicon technology. The modules must be made into 9×4 arrays using 36 solar cells each. Bidding will close on August 3.