Australian team claims 99% recovery rate with solar recycling process

Engineers at the University of New South Wales (UNSW) have developed a new, more effective method to recycle end-of-life solar panels. The technique allows them to quickly and efficiently separate 99% of PV cell component materials.

GoodWe unveils new inverters for C&I applications

China-based GoodWe has developed two new solutions – the ETC 100 kW hybrid inverter and the BTC 100 kW retrofit battery inverter – for commercial and industrial (C&I) solar applications.

Avaada announces $2.44 billion REC funding for energy transition projects

Avaada has signed an agreement with REC for INR 20,000 crore (around $2.44 billion) investment to fund its multiple projects over the next five years.

Govt to retender 20 GWh battery cell capacity under PLI Scheme

The Ministry of Heavy Industries (MHI) will retender the 20 GWh advanced chemistry battery cell capacity that was left unallocated after Hyundai Global Motors Co., one of the winners of the 50 GWh PLI tender, withdrew from the scheme last year.

The Hydrogen Stream: EU, Argentina, Chile, Uruguay to partner on hydrogen

The European Commission and the European Investment Bank have agreed to collaborate with Argentina, Chile and Uruguay on hydrogen, while Masdar, Mitsubishi and Inpex have said that they will use green hydrogen to produce e-methane and polypropylene.

European warehouses store 40 GW of unsold solar panels

Rystad Energy says that about €7 billion ($7.8 billion) of solar panels are now being stored in Europe, but European developers continued to buy solar modules from China throughout the first half of this year.

US manufacturer introduces roof mount with integrated sealant

Pegasus Solar has developed the InstaFlash pre-installed sealant for composite shingle roofs.

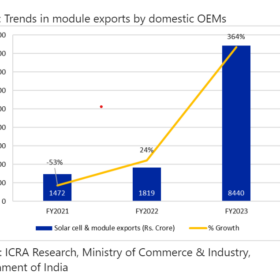

India’s solar PV module exports surge 364% YoY

India exported solar PV cells and modules worth INR 8,440 crore in FY 2022-23. USA was the top destination with a 97% share.

Tata Group to invest over $5 billion in 40 GWh UK battery fab

Tata Group will build a 40 GWh battery factory in the UK to produce batteries for Jaguar Land Rover (JLR) and other EV manufacturers in the UK and Europe.

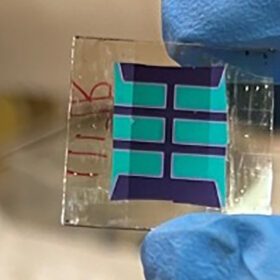

NREL develops perovskite solar cells with 93% bifaciality

The National Renewable Energy Laboratory (NREL) has made highly bifacial perovskite cells with a front-side efficiency of 23%.