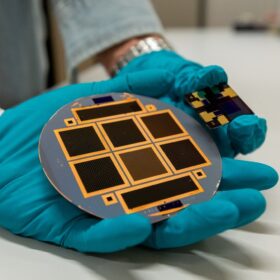

First Solar acquires Swedish perovskite specialist Evolar

First Solar has agreed to pay $38 million to buy Swedish manufacturing startup Evolar AB, as it seeks to expand development of high-efficiency tandem PV tech.

Federal agents raid JinkoSolar factory in Florida

U.S. Homeland Security officers executed a search warrant on a solar panel manufacturing facility in Jacksonville.

Meyer Burger unveils gray solar tiles

Swiss manufacturer Meyer Burger says that in August it hopes to begin distributing its new gray solar tiles, which are already being used in pilot projects.

Annual EV sales in India surpassed 1.2 million in FY 2023

Uttar Pradesh led the yearly electric vehicle sales with a 15.15% share of the cumulative 1.2 million units sold in FY 2022-23. It was followed by Maharashtra (12.72%) and Karnataka (9.14%).

Lithium-iron phosphate prismatic battery cells with energy density of 138 Wh/kg

Chinese energy storage company Imren Battery has introduced its new EVE LF105 lithium-iron phosphate (LFP) prismatic battery cells, which can be used in a wide range of applications, including EVs, renewable energy storage, and other applications.

US solar installers list Qcells, Enphase as top brands

An industry survey led by SolarReviews and NABCEP found two-thirds of solar installers expect high electricity prices to drive demand.

PV manufacturing capacity hit 600 GW in 2022

The new edition of the International Technology Roadmap for Photovoltaic (ITRPV), published this week, finds that 295 GW of PV modules was shipped in 2022, and that prices for silicon PV modules fell by 7% over the year. The report finds that price premiums for n-type modules are now marginal, and the technology grew to represent 15% of the market, and is expected to keep growing over the coming decade.

Borosil Renewables’ solar glass capacity in Germany increases to 350 tpd

Borosil Renewables said the solar glass capacity of its German arm GMB Glasmanufaktur Brandenburg GmbH has increased to 350 tonnes per day (tpd) from 300 tpd following the modification and cold repair of its furnace.

The PV scientific community’s rush to the latest efficiency record

Perovskite-silicon tandem technology expert Gianluca Coletti explains what cycles the PV industry and scientific community experience every time there are new jumps in power conversion efficiencies at cell level. According to him, we are experiencing a much faster turnover of efficiency records typical of the early stage of development of a new technology holding an incredible potential.

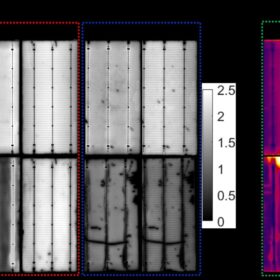

Scientists warn of heat-induced failure risks in HJT glass-backsheet PV modules

University of New South Wales researchers have identified four failure modes caused by damp heat in heterojunction solar panels with a glass-back sheet configuration. The failures could result in power losses ranging from 5% to 50%.