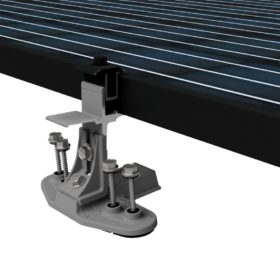

SnapNrack introduces solar mount that attaches to module before roof

SnapNrack’s TopSpeed solar mount begins installation on the ground, which limits time spent on rooftops.

Wafer, cell prices continue to rise

Wafer prices rose by between 24% and 36% this week, according to new data from the China Nonferrous Metals Industry Association (CNMIA).

Emmvee gets Fraunhofer ISE on board for solar cell line

India’s Emmvee Group has appointed Germany’s Fraunhofer Institute for Solar Energy as the technology partner for its upcoming 1.5 GW PV cell manufacturing facility.

New EV battery offers 50% more density than traditional lithium-ion batteries

Ionblox says it will use $32 million of series B funding to support the buildout of a novel silicon anode electric vehicle battery.

IIT-Madras Research Park signs thin-film R&D MoU with First Solar

IIT Madras Research Park and US-based First Solar will cooperate on a range of research and development (R&D) activities including the localization of thin film and other next-generation PV technology supply chains in India, high-volume manufacturing, PV module testing, and high-value recycling.

Pausing ALMM will hit solar manufacturing investments, say industry bodies

The implementation of the ALMM (The Approved List of Models and Manufacturers) mandate is crucial to protect INR 53,773 crore of investments that India would require over the next 3-4 years to indigenize the domestic solar manufacturing value chain, say manufacturers.

Survey shows 34.3% failure rate for residential inverters over 15 years

The Bern University of Applied Sciences in Switzerland has published the initial results of a survey on the durability and performance of residential PV inverters and power optimizers over a 15-year period. They found that more than 65% of the inverters did not present yield-relevant faults by their 15th year of operation.

Adani Green Energy Q3 profit soars 110% YoY

Adani Green Energy Ltd, the renewable energy arm of the diversified Adani Group, reported a consolidated net profit of INR 103 crore in the three months ended Dec. 31, 2022.

Polysilicon price rebound continues

Polysilicon prices started to rise in the second half of January, according to new data from the China Nonferrous Metals Industry Association (CNMIA).

Reflective membrane to increase albedo, power yield in bifacial PV projects

Germany-based Solmax has developed a reflective membrane made of polyethylene resins and coated with a thin white polyethylene layer that reflects ultraviolet (UV) rays. The company claims the membrane can increase the energy yield of a bifacial PV project by between 5% and 20%, depending on the plant configuration.