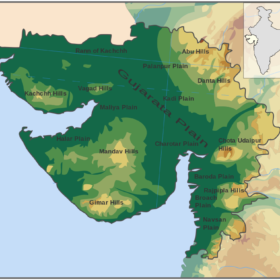

Electric mobility startup Matter to invest INR 1,500 crore in Gujarat

The Ahmedabad-based technology startup has committed to funding INR 1,500 crore in electric vehicles and energy storage over the next five years in the state.

Puffer fish inspired floating PV structure

With a new system for floating photovoltaic power plants, engineers from Germany want to make the application cheaper, higher-yielding, and safer. The result is somewhat reminiscent of a pufferfish, which also gave the system its name.

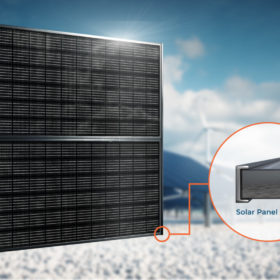

Canadian BIPV module maker releases 790 W panel

Mitrex Integrated Solar Technology has developed a new solar panel with 19.5% efficiency that measures 2,036 mm x 1,992 mm x 40 mm and weighs in at 42 kg. It can operate with a system voltage of 1,000 V and has a power temperature coefficient of -0.36% per degree Celsius.

Shirdi Sai Electricals signs MoU with German firm to build 4 GW solar fab

German engineering and consulting firm Viridis.iQ GmbH will assist in conceptual design to construction and commissioning of the 4 GW vertically integrated poly-to-modules solar factory.

Photovoltaic rotary energy system for domestic applications, high-rise buildings

Developed by scientists in Turkey, a system prototype has operated at lower PV module temperatures and removed most of the dust accumulation. The researchers are now planning to improve the device by applying MPPT converter topologies.

The long read: Cloud looms over PV’s silver lining

Should heterojunction solar technologies be temporarily shelved? Could copper plating replace screen-printed silver conductive surfaces in cells? Why are tandem cells a likely successor to PERC? Brett Hallam recently sat down with Natalie Filatoff in Sydney to explain the findings of a new study by UNSW that sought to answer these controversial questions.

Invergy to set up residential-solar inverter factory in India

Director Deepak Pandey is confident the company’s hybrid devices – which are lead-acid and lithium battery compatibility – will replace the existing market.

Pixon will expand solar module factory to 1 GW, plans backward integration

The Gujarat-based solar module manufacturer, which currently has 400 MW module fab operational, is expanding capacity to 1 GW with the addition of 600 MW mono PERC line. Having started EVA film manufacturing, it also plans to get into the production of aluminium frames and backsheets.

Intersolar 2021 opens in Gujarat

The three-day solar exhibition kicked off today at Helipad Exhibition Center in the Gandhinagar district of Gujarat. On the first day, Indian solar manufacturers Adani Solar, Pixon, Saatvik among others shared with pv magazine their aggressive plans to ramp up production capacities and launch new technologies. We also caught up with inverter player Invergy, which plans to open its manufacturing capacity soon in India.

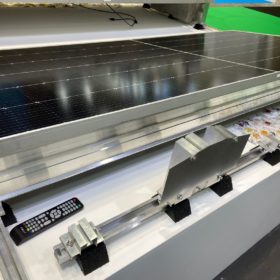

Mounting system for rooftop PV relying on large-size solar modules

Developed by Spanish manufacturer Alusín Solar, the new mounting system is claimed to be, currently, the only one on the market that provides six fixing points for a solar panel in ballast-secured structures.