The long read: First Solar – ‘India presents a big market opportunity for us’

Sujoy Ghosh, First Solar’s vice president for India and the Asia-Pacific region, speaks to pv magazine about the company’s plans to set up a 3.3 GW module fab in India to service the local market.

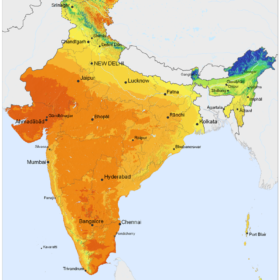

Emerging trends in the Indian solar power sector

The Indian solar power sector is undergoing a technology-backed transformation at every stage from manufacturing to installation to improve cost and performance efficiency.

Vietnamese manufacturer unveils PV module for agrivoltaics

Vietnamese manufacturer Irex has announced a new glass-glass solar panel with a power output of 265 W and a power conversion efficiency of 18.1%.

Silicon metal and aluminum industries hit by China power shortages

A combination of booming demand for coal-fired power and a shortage of the black stuff – exacerbated by a political row with Australia – have forced up prices to the extent fossil fuel generators are making a loss on every unit of electricity they produce. pv magazine‘s Vincent Shaw considers the potential solutions.

Emmvee to set up 3 GW solar cell and module factory in Karnataka

Coming up at Dobaspet town in Karnataka, this will be Emmvee’s second solar manufacturing investment in the Indian State after the existing 500 MW module plant.

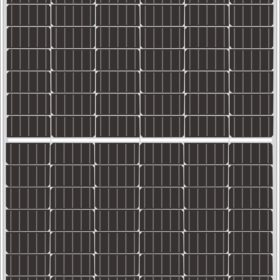

Pixon unveils 375-410 Wp half-cut modules with 20.4% efficiency

The Indian solar manufacturer has unveiled mono PERC half-cut-cell modules with output ranging from 375Wp to 410 Wp. The five-busbar modules can be used in all installations including off-grid, residential, commercial and industrial, and utility-scale.

Solar tile with 14.2% efficiency from Denmark

Dansk Solenergi ApS has developed a 13.6 kg tile that can be used for both new buildings and building renovation. The device is currently being produced in Denmark, where the company operates a 40 MW line.

The long read: First Solar goes to India

First Solar has announced plans to establish a new 3.3 GW manufacturing facility in India. Representing an investment of $684 million, the move demonstrates the thin-film PV manufacturer’s confidence in India’s solar growth and the increasingly favorable policy environment for domestic solar PV production.

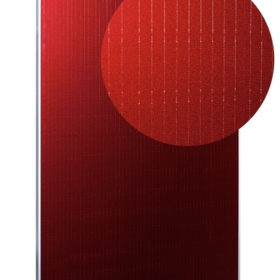

Red BIPV solar module from Italy

The module is available with wattages of 230-245 W and can reach an efficiency of up to 13.45%. The panel is part of a new series of colored products that includes silver and orange modules.

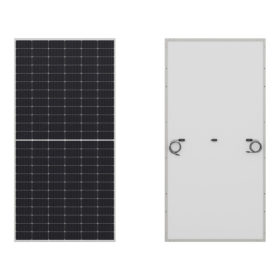

Sharp launches 540 W half-cut PV module with 20.9% efficiency

The IEC/EN61215 and IEC/EN61730-certified panel features 144 half-cells based on M10 wafers and a 10-busbar design. Its operating temperature coefficient is -0.341% per degree Celsius and its power tolerance reaches up to 5%.