Rayzon Solar to add 1.2 GW of mono PERC module capacity

The Gujarat-based manufacturer is scaling its production lines up to 1.5 GW with the addition of 1.2 GW of mono PERC output capacity by the end of December. The new line will produce up to 600Wp panels with an efficiency of 21.4%.

Micro-inverter for balcony solar modules

Two different devices designed by German manufacturer Bosswerk can feed up to 300 or 600 watts into the home network. The company offers a 12-year guarantee.

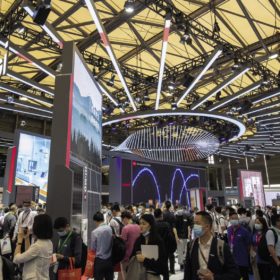

The long read: SNEC’s solar trends in 2021

All eyes are drawn to China every year for SNEC, the world’s biggest solar PV expo, as it invariably features a large number of new products from the key Chinese manufacturers. Vincent Shaw was on the scene in Shanghai this year and took the opportunity to take the industry’s pulse.

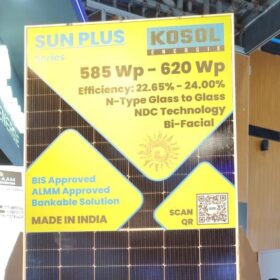

No excuses, India must ramp up solar manufacturing to reduce reliance on imports

Through various initiatives and schemes, the Indian government has created a conducive environment for industry stakeholders to expand domestic manufacturing. The industry should seize the opportunity to ramp up capacity and manufacture emerging technologies such as monocrystalline (mono-Si), bifacial and half-cut cells, micro-inverters, and tracking equipment, all of which promise further solar efficiency gains over the coming years.

Solar module cooling techniques for the desert

Saudi scientists have tested several cooling technologies for solar panels and have found that active techniques work better than passive ones under harsh climatic conditions. The most effective one consists of a system based on four heat pipes immersed in a box of liquid, as liquid bulk, integrated with the back of the solar panel.

JinkoSolar claims 23.53% efficiency for n-type, TOPCon, monocrystalline panel

The PV module relies on Jinko’s TOPCon mono cell technology, for which a record efficiency of 25.25% was announced in late May. TÜV Rheinland has confirmed the result.

All solar cell efficiencies at a glance

The research group led by Professor Martin Green has published Version 58 of the Solar cell efficiency tables. He spoke with pv magazine about the criteria with which these tables are compiled and the importance of result certification by independent third parties.

Gravita Group enhances lead recycling capacity at Africa plant

The Jaipur-headquartered company carries out smelting of lead ore, lead concentrate, lead battery scrap, and aluminum scrap to produce secondary lead metal and aluminum ingots.

Where the ALMM listing requirement went wrong for India’s solar mission

The idea behind introducing the Approved List of Models and Manufacturers (ALMM) was to have a quality benchmark for solar modules. However, in its current form, it is more of a non-tariff barrier for foreign manufacturers and limits solar developers in terms of the choice of module wattage and make.

Trina Solar achieves 23.03% efficiency for 210 mm PERC solar module

The result was confirmed by Germany’s TÜV Rheinland and TÜV Nord.