Solar photovoltaic quality control and waste management in India

As PV waste is set to rise rapidly in the coming decades, India needs to invest in efficient recycling technologies and devise a clear-cut policy for the safe disposal of PV waste. Guidelines for stringent quality checks and validation for both imported and locally produced solar panels are also needed to avoid early-loss solar waste.

Fraunhofer ISE unveils 68.9%-efficient III-V solar cell for laser energy transmission systems

The German research institute said the gallium arsenide cell has achieved the highest efficiency to date for the conversion of light into electricity.

LNJ Bhilwara, Replus to set up a 1 GWh lithium-ion battery plant

LNJ Bhilwara, a diversified business group with presence in graphite electrode manufacturing, has formed a joint venture with Pune-based Replus Engitech to create lithium battery solutions for both e-mobility and stationary applications. The JV aims to have 1 GWh capacity operational in Pune by mid-2022 and eventually scale it to 5 GWh by 2024.

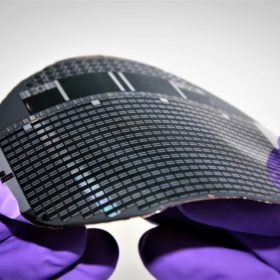

1366 Technologies merges with Hunt Perovskite Technologies

U.S. thin-film manufacturer First Solar and Bill Gates-owned Breakthrough Energy Ventures (BEV) are among the investors in the new company, which is called CubicPV and is expected to develop multi-junction perovskite solar cells with efficiencies of around 30%.

New renewables cheaper than legacy coal or gas for almost half the world’s population

Electricity bill payers in nations as diverse as China, India, Germany, and Greece should be aware new solar projects can now generate electricity cheaper for them than legacy coal and gas-fired plants.

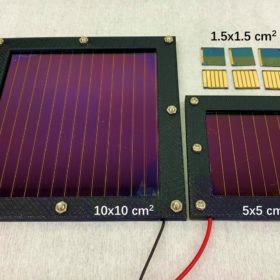

New perovskite material for 23.5%-efficient solar cell

Researchers in Japan have found a new way to fabricate one of the most promising perovskite materials for PV application — the α-formamidinium lead iodide known as α-FAPbI3. With a pre-synthesized version of this material, they were able to produce a cell with a power conversion efficiency of 23.5% and a lifespan of more than 2,000 hours.

The long read: Rethinking PV module degradation

PV module making is a brutally competitive industry. And for Slovenian module maker Bisol, in business since 2004, one of the keys to success has been to remain focused on the value its products deliver to the customer. And as company founder and CEO Uroš Merc explains, in 2021 this means reimagining module degradation.

Goldi Solar supplies 12 MW of modules for a Tamil Nadu project

The Gujarat-based solar panel manufacturer and EPC provider has completed the supply of 72GN polycrystalline modules with peak power output of 335W each for a project installation by Peak Qualish Systems.

Reliance Industries unveils $10-billion plan for solar and energy storage

The diversified business group will invest over INR 60,000 crore ((US$ 8.1 billion) over the next three years to build Giga factories for solar, energy storage, electrolyzers, and fuel cells, respectively, to create a fully integrated, end-to-end renewables energy ecosystem. Additional INR 15,000 crore (US$ 2 billion) is planned to create a value chain, partnerships, and future technologies.

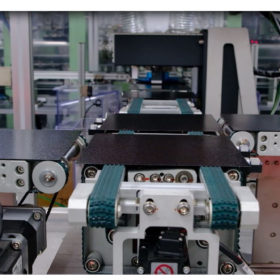

India could add 13.75 GW of solar module and 6.9 GW cell capacity by December next year

The government’s renewed efforts to curb solar equipment imports and upscale domestic manufacturing have started bearing fruits. The launch of the production-linked incentive (PLI) Scheme and the imposition of a basic customs duty (BCD) on imports have favored domestic capacity expansion.