Rayzon Solar to manufacture TopCon modules in USA

Chirag Nakrani, director of Rayzon Solar, told pv magazine that their 500 MW PV module manufacturing facility in the USA will start production of TopCon modules by June 2024.

Neogen signs technology license agreement with Japanese major to manufacture lithium battery electrolytes in India

With this arrangement, Neogen gets access to a proven global technology to manufacture electrolytes at scale for lithium-ion batteries in India.

Kosol Energie buys 850 MW PV module production line from SC Solar

The Indian solar manufacturer is expanding its annual PV module production capacity to 1.1 GW with the installation of a new 850 MW line from SC Solar. It plans a cumulative PV module capacity of 1.9 GW by the end of the current fiscal with the commissioning of a second 850 MW line.

Grew wins 2 GW wafer-to-module capacity under PLI Scheme

Ahmedabad-based Grew Energy will receive incentives of INR 566.71 crore for 2 GW of integrated wafer-cell-module manufacturing.

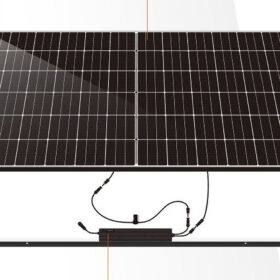

US manufacturer releases new dual solar optimizer

Enteligent, a residential PV solutions specialist, has introduced an optimizer model that can be paired with two solar panels. It claims that it features rapid shutdown and monitoring capabilities.

Amp Energy India wins 1 GW solar cell and module capacity under PLI Scheme

The renewable energy developer has won incentives of INR 140 crore ($17 million) for 1 GW of integrated solar PV cell and module production capacity.

Jakson signs 600 MW PV production equipment deal with Jinchen

Jakson Group has placed the order for a 600 MW PV production line with Jinchen. The fully automated line will be equipped to produce the latest p-type, n-type, and G-12 solar modules in both mono-facial and bi-facial variants.

DAH Solar unveils solar kit for balconies, rooftops

China’s DAH Solar has developed a turnkey solar system with a plug-in connection for residential applications. The kit can reach a maximum size of 2,279 mm × 1,134 mm × 32mm and weighs up to 59.8 kg.

India could become world’s second-largest solar manufacturer by 2026

India’s solar module manufacturing capacity could reach 110 GW by 2026. It will also have a notable presence in all upstream components of PV manufacturing, such as cells (59 GW), ingots/wafers (56 GW), and polysilicon (38 GW).

NTPC Ltd seeks bifacial modules for Nokh solar project

NTPC has tendered the bifacial PV module package for the Nokh solar project in the Indian state of Rajasthan. Only domestic manufacturers are eligible to bid. Bidding closes on April 25.