ReNew Power to employ Israeli bots for solar panel cleaning

Israeli firm Airtouch Solar has landed a $7.6 million deal to deploy its water-free cleaning robots for the Indian developer’s three solar farms in Rajasthan.

Longi unveils two PV modules for distributed generation

The two new products will be part of the Hi-MO4m panel series for rooftop applications. Their efficiency ranges from 19.2% to 21.2%.

REC launches 405 W black solar module with gapless design

The new heterojunction panel series features an efficiency of up to 21.9 % and an operating temperature coefficient of -0.26% per degree Celsius.

Premji-backed Indian firm to make solar glass

Float glass manufacturer Gold Plus Glass Industry confirmed to pv magazine its plans to establish a solar glass factory with a capacity of 300 tonnes per day. The plant, located in south India, will be operational by September 2023.

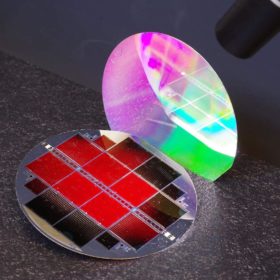

Fraunhofer ISE achieves 35.9% efficiency for III-V triple-junction solar cell based on silicon

The cell, which looks externally like a device with a two-terminal architecture, was built with III-V semiconductor layers that were connected to the silicon sub-cell on the atomic level. The cell may be used in electrically powered aircraft and drones.

The long read: Understanding solar MLPE

Module-level power electronics, most often in the form of power optimizers and microinverters, offer a range of value propositions, including advanced monitoring capabilities. But how much can the little box behind the module really see, and how much do operators actually need to know to keep a power plant running optimally?

First Solar claims lowest module degradation rate in the industry

The US cadmium telluride thin-film module maker said its Series 6 CuRe panels are able to retain 92% of its performance at the end of the 30-year warranty. The improved stability of the product was achieved by eliminating copper and placing Group V elements such as antimony or arsenic onto the tellurium crystal sites.

Covid impact: Solar imports dipped 75% in ten months

Coronavirus disruption has been cited as the chief culprit as imports from China, Thailand and Vietnam slumped from April to January, but safeguarding duty also appears to have had an impact, with unaffected imports from nations such as Myanmar, Chad and Russia on the rise and Malaysian trade keeping steady.

BHEL issues global tender to select monocrystalline module partners

Bharat Heavy Electricals Ltd (BHEL) seeks module supply partners for an aggregate 750 MW of panels as it intends to participate in the tender for 500 MW Rewa solar park in Madhya Pradesh. Bidding closes on April 27.

Trina launches 670W Vertex solar module and tracking systems in India

The Chinese solar manufacturer has launched the 670W Vertex solar module in India that offers an efficiency of up to 21.6%. It has also fielded two models of panel tracking solutions from its TrinaTracker business.