Meyer Burger to commercialize 29.6%-efficient perovskite tandem solar cells

Meyer Burger is working with several research institutes in Switzerland and Germany to integrate perovskite tandem technology into its manufacturing processes.

Cooling down photovoltaic panels with concrete

Scientists in Italy have proposed the use of radiative coolers made of cementitious materials to reduce the operating temperature of solar panels. The novel system configuration consists of a stack made by a reflector, a cement-based radiative cooler, and a bifacial solar cell.

Adani appoints EIL as owner’s engineer for polysilicon project

Engineers India Ltd (EIL) has been appointed as owner’s engineer for Adani Group’s 30,000 MTPA polysilicon and 500 MTPA monosilane project in Gujarat.

Color-sensing tech to remove dirt from solar panels

South African researchers have developed a new cleaning system for solar panels that uses a color-sensing light-to-frequency converter to detect dirt. It can reportedly remove around 95% of the dust from a PV panel in less than a minute, at a lower cost than other systems.

Roadblocks to rooftop solar

India is long way behind its rooftop solar target of 40 GW by 2022 with just 10.4 GW installed till September (Source: Bridge To India). Amplus Solar team speaks to pv magazine about factors holding back rooftop solar development in India.

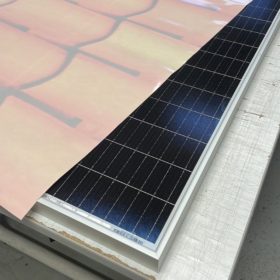

Customizable sticker to turn solar panels into advertising billboards

An Italian startup has created a fully recyclable sticker that can be used to cover solar panels on rooftops or facades. It replicates high-definition images that can help to improve the aesthetics of solar arrays or turn PV facades into advertising billboards.

New foldable solar system for rooftop applications

German manufacturer Kopp has developed an easy-to-install, four-module foldable PV array. The system uses n-type TOPCon solar modules with outputs of 430 W and efficiency ratings of 22.02%

Adar Poonawalla-backed homiHydrogen to set up 1.5 GW electrolyzer fab in India

The $50 million electrolyzer factory is expected to start production in 2023. It will produce all four types of commercially available electrolyzers.

Neuron Energy to invest INR 50 crore in lithium battery pack business

The Mumbai-headquartered lithium battery manufacturer plans working capital finance of INR 35 crore and equity investment of INR 15 crore to increase production capacity and fulfil orders from large OEMs.

Saatvik appoints solar panel distributor for Rajasthan

Haryana-based Saatvik Solar has appointed Etrica Power as the distributor of its solar panels in the Rajasthan region.