Longi signs 1.3 GW solar module supply deal with L&T

The Chinese module maker will supply 1,292 MW of PV modules for Larsen & Toubro’s two solar EPC projects in Saudi Arabia.

Goldi Solar launches 520-550 Wp mono PERC DCR solar modules

The modules are built with made-in-India cells and therefore eligible for government projects and schemes mandating domestic content requirement (DCR).

PV shade screens for greenhouses, agrivoltaics

A Saudi Arabian startup has developed a modular solar panel for agrivoltaic applications. It is specifically designed for locations with high solar radiation levels and protects plants and crops from excess sunlight.

Itochu to start recycling solar modules

Japan’s Itochu has announced a new tie-up with France’s Rosi Solar, which develops tech to recover and recycle high-purity silver, copper and silicon from solar modules.

India installed 11.2 GW of solar in first nine months of 2022

The nation installed 9.3 GW of utility-scale solar, 1.3 GW of rooftop arrays, and 0.6 GW off-grid PV projects from January to September this year.

Poweron unveils new hybrid inverters for residential solar

The Indian manufacturer has introduced wall-mount hybrid solar inverters with nominal power ratings of 3.68 kW, 4.6 kW and 5 kW. The inverters are compatible with both lead-acid and Li-ion battery.

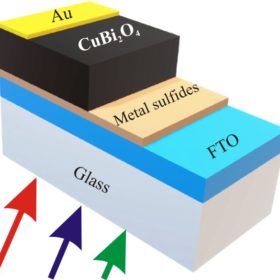

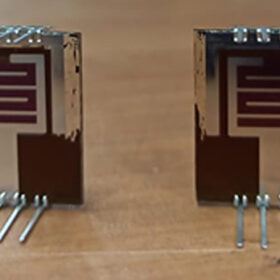

Scientists make first attempt to design solar cells based on kusachite

Indian scientists have designed a thin-film solar cell that uses a mineral made of binary copper(II) and bismuth(III) oxide. They identified a cell design with a tin sulfide buffer layer that offers efficiencies close to 27.7%.

Birla Carbon joins project to develop lithium battery-grade graphite from biocrude

The carbon black solutions manufacturer has embarked on a collaborative project to develop lithium battery-grade graphite sustainably using renewable feedstocks.

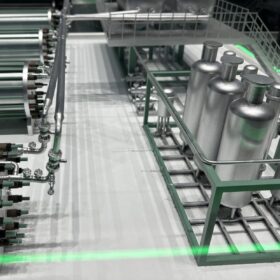

Qcells, European consortium launch production line for tandem silicon-perovskite solar cells

South Korea-based Qcells and a research group led by Helmholtz-Zentrum Berlin (HZB) have established a pilot manufacturing line for silicon-perovskite tandem cells in Thalheim, Germany. The project aims to speed up the technology’s mass manufacturing and market penetration.

Sunova Solar releases 575 W n-type PV panel with 22.2% efficiency

Sunova Solar is offering five versions of its new solar panels, with power outputs from 555 W to 575 W and efficiencies ranging from 21.4% to 22.2%. They have a temperature coefficient of -0.31% per degree Celsius.