Covid-19: The going gets tough for solar manufacturers

Solar season had already started in the month of March. The demand for solar consumption is the highest during April-June quarter as summer picks up. This is the time when factory runs with full efficiency. India was estimated to install nearly 8 GW of solar panels in 2020, in which 90% consumption happens in utility-scale […]

Can solar industry tide over the Covid-19 crisis?

Planning ahead is crucial to ensure the Indian solar industry bounces back quickly and the slowdown is not carried forward to 2021-22, say BloombergNEF analysts even as they estimate 75% fall in PV imports in the first quarter of year 2020 over the previous quarter and revise annual capacity addition forecasts.

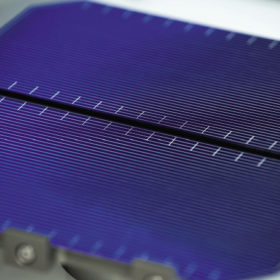

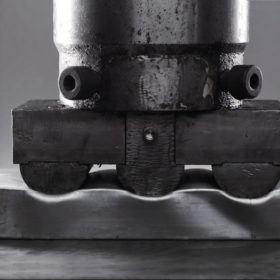

The long read: Laser focused

Solar manufacturing’s recent move toward larger wafer/cells throws into focus the need for effective cell-cutting techniques to handle the processing of these cells into half cut or even smaller formats. pv magazine looks at the landscape for cell cutting, as the technology reaches maturity and moves into the mainstream of cell/module production.

Europe’s Wamtechnik, ION Energy partner to enable electric excavator

The European Li-ion battery manufacturer has partnered with the Mumbai based battery management system provider on the design and deployment of an electric excavator that would operate in subzero temperatures (below -20°C).

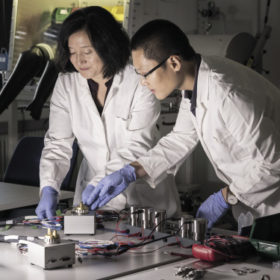

IIT Bombay group suggests method of detecting early-stage discoloration in EVA encapsulants

A new, non-destructive technique has been proposed by researchers who say identifying early-stage discoloration in EVA encapsulants can help detect degradation in solar panels before power output is affected. The IIT Bombay group used an ultraviolet accelerated aging test during 34 days on three encapsulant samples.

Analyst expects recovery for PV and storage supply chains

U.S.-owned analyst Wood Mackenzie expects solar demand to decline but predicts the market will recover, with the prospects for the energy transition remaining intact.

Cheaper flow batteries with new membrane

US scientists claim to have discovered a membrane which could lead to cheaper large scale flow batteries. The material is an ion-selective, aqueous-compatible polymer with intrinsic microporosity known as AquaPIM and is said to have tunable thickness and high conductivity in aqueous electrolytes.

US based XNRGI opens lithium-ion battery factory in India

Based in Gurugram, the factory is spread over 30,000 sq.ft and can produce 240 MWh of high-temperature battery storage solutions annually. These batteries can charge to 80% capacity within two hours and operate in excess of 55ºC, which makes them suitable for hot, humid tropical climates.

The long read: Stored potential

Demand for batteries is going nowhere but up, as new factories seem to appear almost every week with promises to power electric vehicles, consumer electronics, and grid-connected storage. But the lithium-ion technology that all of these rely on is not without drawbacks, and a whole host of new storage solutions is eager to get out of the laboratory.

Optimistic solar outlook dimmed by COVID-19 – Bridge To India

Developers are also expected to drag their heels over project completion during the first half of the year as the safeguarding duty applied to imported Chinese and Malaysian solar products is due to expire at the end of July.