Attero enters solar panel recycling MoU with NISE

Attero and the National Institute of Solar Energy (NISE) have signed a memorandum of understanding for research and development of solar panel recycling technology in India.

Lithium-ion battery recycling plant comes online in Arizona

The opening of Ecobat’s new facility is just one of many indicators that U.S. battery recycling is on the rise.

PV module recycling tech based on electrohydraulic shockwave fragmentation

An international research team has developed a new machine that utilizes shockwaves to separate the different materials of a solar PV module. Chemical processes can be further used to extract silicon and silver. Results show the recovery of more than 99.5% of the original weight of the panels.

Transforming discarded batteries into valuable resources

Rather than viewing battery recycling as waste management, it should be reframed as an economic and industrial opportunity. Advanced recycling techniques can recover up to 95% of lithium, cobalt, and nickel, reducing India’s reliance on raw material imports.

Challenges and opportunities for lithium-ion battery recycling in India

A new study examines the current status of lithium-ion battery consumption, and challenges and opportunities in the Indian recycling landscape.

Epic Energy enters licensing agreement with C-MET for lithium battery recycling

Epic Energy has entered a ten-year licensing agreement with the Centre for Materials for Electronics Technology (C-MET) for recycling of end-of-life lithium batteries (excluding lithium ferro phosphate batteries) using a hydrometallurgical process.

Turning climate commitments into competitive advantages: How businesses can benefit from sustainability

The best businesses aren’t just adapting to the changing landscape; they’re leveraging sustainability to drive innovation, reduce costs, and build stronger relationships with their customers and stakeholders. Business leaders are turning sustainability into a growth driver rather than a cost center by adopting the right practices.

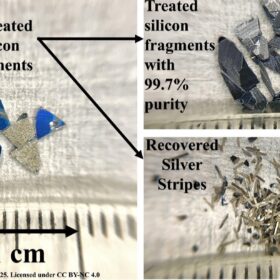

UNSW develops PV panel recycling method that recovers cell metals for upcycling

UNSW researchers were able to recover silicon from end of life solar PV panels pure enough for re-use in silicon carbide-based devices. Their novel multi-step method which includes thermal and chemical processes, also recovers silver.

Envirostream Australia signs battery recycling deal with Hithium Energy

Envirostream Australia, a subsidiary of Livium, has signed an exclusive recycling agreement with Hithium Energy to recycle lithium-ion batteries supplied by Hithium to Lightsource bp’s Woolooga solar farm in Queensland, Australia.

Ace Green to build India’s largest LFP battery recycling facility

Ace Green Recycling plans to establish 10,000 metric tons of lithium iron phosphate (LFP) battery recycling capacity per year in India by 2026.