Vikram Solar modules top performer for fifth consecutive year

Vikram Solar’s Paradea mono PERC 144-cell bifacial glass-glass modules have won the Top Performer position in PV Evolution Labs’ 2023 PV Module Reliability Scorecard. With this, Vikram Solar has claimed the title for the fifth consecutive year and the sixth time in the last seven years.

Avoiding PV buyer’s remorse

New entrants to solar equipment procurement may be surprised to encounter constantly amended contract terms, index-linked price rises, and near-worthless defect warranties, but they reflect recent supply chain troubles. Clean Energy Associates’ Martin Deak offers a buyers guide.

IIT Kanpur, Lohum collaborate on lithium battery testing for safety and sustainability

IIT Kanpur and Lohum will work together to advance lithium-ion battery testing technology and techniques for evaluating battery raw material quality. Lohum will additionally sponsor R&D labs at IIT Kanpur, provide a research fellowship to Ph.D. students, and help IITK commercialize its research outcomes.

Indian PV market must invest in quality infrastructure

In its latest monthly column for pv magazine, the International Renewable Energy Agency shares a series of recommendations gathered from sector experts to help India reach its ambitious solar targets. According to its experts, Quality Infrastructure (QI) will be crucial for the country’s PV market in the years to come. QI is an interdependent ecosystem of the different elements (accreditation, certification, standards, testing, metrology, inspection & monitoring) working together in harmony, and all associated services should be developed in unity and not in a piecemeal fashion. A sound and internationally harmonized QI not only ensures that PV products and services deliver as expected by customers and national energy authorities, but also enables more efficient and competitive markets based on a global economy on scale.

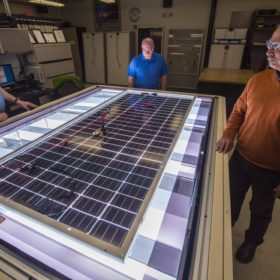

Vikram Solar R&D lab receives NABL accreditation

The West Bengal-based solar manufacturing and EPC solutions company said its lab is now accredited by the National Accreditation Board for Testing and Calibration Laboratories to test high-efficiency PV panels.

Elusive longevity

The expected lifetime of PV inverters is significantly shorter than that of modules. In many projects, inverter replacement is included in financial calculations from the start, despite the high costs. Research is being conducted into the causes of faults to develop more durable inverters and components. But plant design can already improve the lifespan of inverters in use today, reports pv magazine Germany’s Marian Willuhn.

Schüco warns of more solar modules with defective backsheets

Schüco has expanded its recent warning letter about potential solar panel defects to include more products. The new list includes PV modules the company delivered between 2010 and 2014.

Why do solar power plants work inefficiently?

When choosing a solar power plant, individuals and businesses pay the most attention to its power – after all, this will determine how much electricity will be produced. Other equipment, systems and sensors that allow monitoring and analysis of the operation of the power plant are often underestimated. But they shouldn’t be: the solar power plant will be used for several decades, so various failures and poor-quality monitoring can have a significant impact on the efficiency of electricity production.

Monitoring degradation for 13 module types

In a study that began in 2016, US scientists purchased 834 PV modules, representing seven manufacturers and 13 module types, and installed them in various climate conditions to observe their performance over time. The results show that, while plenty of opportunities still exist to extend module lifetimes and reduce performance loss in the field, reductions in the manufacturing cost of PV have not come with an increase in their degradation rate.

Flasher for a solar PV lab

Sun simulator is considered to be the heart of a testing or a calibration lab used to test solar PV panels, indoor under controlled and repeatable conditions. There are various parameters to be considered while selecting one.