Mitigating risks in new PV technologies

The solar energy industry continues to push the boundaries of efficiency and reliability. However, as innovative photovoltaic cell and module technologies emerge, they also bring a new set of challenges in durability and performance. A new report from IEA PVPS Task 13, titled “Degradation and Failure Modes in New Photovoltaic Cell and Module Technologies,” offers a comprehensive analysis of degradation and failure mechanisms in current photovoltaic technologies.

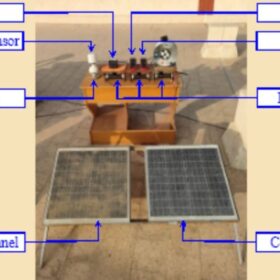

Anti-soiling coating increases PV panel current in arid regions by 64.7%

Scientists in Egypt have created an anti-soiling coating for solar panels by mixing ethanol, deionized water, ammonium hydroxide and tetraethyl orthosilicate. They tested a coated panel outdoors for ten months and found that the panel showed a 64.7% higher current compared to reference modules without coating.

Kärcher to deepen presence in Indian market with tailored cleaning solutions

Kärcher India, the Indian arm of Germany-based cleaning technology company Kärcher, is eyeing the growing demand from large-scale commercial and industrial solar installations in India and also looking to tailor its solutions for residential rooftop solar installations.

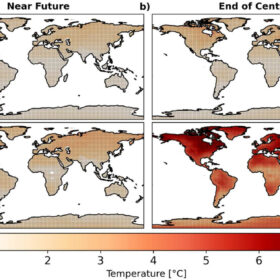

Solar productivity negatively impacted by emissions and aerosols, study finds

A study by engineers at UNSW, published in the Renewable Energy journal, shows that aerosols and greenhouse gas emissions reduce the productivity of photovoltaic installations and that this differs according to the global region.

Physics-based model to predict soiling losses in bifacial solar modules

Scientists in India have developed a novel way to predict soiling accumulation on bifacial modules. Their approach considers dust deposition, rebound, and resuspension phenomena.

The impact of soiling on PV module transmittance

A European group has looked into the soiling impact on PV modules in Oman. They have collected 60 samples, based on season, month and tilt angles.

All antireflective solar module coating techs at a glance

Scientists in the United Kingdom have investigated the durability and performance of all antireflecting coatings for solar modules and said further work is needed to improve industry standards. Their review addresses single-layer and multi-layer techniques and provides insight on their costs and viability.

Why do solar power plants work inefficiently?

When choosing a solar power plant, individuals and businesses pay the most attention to its power – after all, this will determine how much electricity will be produced. Other equipment, systems and sensors that allow monitoring and analysis of the operation of the power plant are often underestimated. But they shouldn’t be: the solar power plant will be used for several decades, so various failures and poor-quality monitoring can have a significant impact on the efficiency of electricity production.

Have your say on the future of automation in solar O&M

Cost efficiency while maximizing power output is the name of the game in solar project development and asset management. And the automation of the provision of utility scale solar operations and maintenance (O&M) is fast becoming one of the most compelling opportunities. Help shape the future of automation in solar O&M by completing this first-of-its kind survey.

The long read: Dealing with dust

Sand and dust are a PV plant operator’s worst nightmare. Performance losses due to soiling, or “the dust effect,” are a cause for innovation among O&M providers, particularly in dry and dusty regions that are otherwise ideal locations for large-scale solar installations. Yazeed Al-Mousa examines the latest robotic cleaning solutions, as well as the software and sensors that help plant operators with the tricky economic decision of when to actually start cleaning.