Avaada Group closes $1.3 billion funding round

The integrated energy company has closed $1.3 billion in financing for its green hydrogen, green methanol, green ammonia, solar manufacturing, and renewable power generation ventures.

IH2A submits plan for $5 billion national green hydrogen hubs by 2030

Industry body India Hydrogen Alliance has submitted a plan to the government to build five large national green hydrogen corporations with a collective enterprise value of $5 billion by 2030. The plan shows public finance support, in the form of CAPEX and offtake incentives for National Green H2 Hubs, is crucial for creating financially viable green hydrogen infrastructure, especially in the initial 2024-30 period.

L&T advances renewables infrastructure for world’s largest green hydrogen plant

Larsen & Toubro (L&T) is set to begin constructing the renewable energy generation, storage, and grid infrastructure for the green hydrogen production facility in Saudi Arabia, as it has made significant progress from design to procurement.

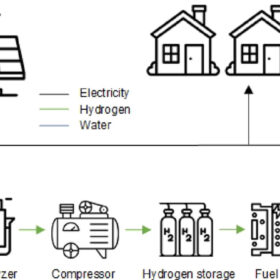

Novel approach to PV-battery-electrolyzer-fuel cell systems

TU Delft scientists have proposed a new methodology for off-grid PV-battery-electrolyzer-fuel cell systems in remote areas.

Green hydrogen market could hit $850 billion in 2050

Research outfit Rethink Energy says the green hydrogen market could reach $850 billion in value by 2050.

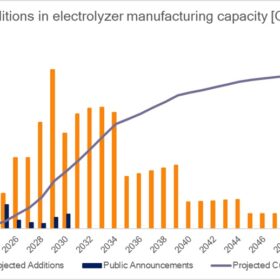

Larsen & Toubro’s electrolyzer fab to start production this fiscal

The Indian multinational EPC company is setting up a pressurized alkaline electrolyzer factory with a capacity of 1 GW per annum. It expects to produce the first few electrolyzers from this facility by March next year.

All major ports should switch to over 90% renewable energy by 2047, say new guidelines

The recently issued green port guidelines emphasize using clean energy in port operations and developing port capabilities for storage, handling, and bunkering of greener fuels such as green hydrogen, green ammonia, and green methanol.

Green hydrogen demand to reach 2.85 MMT/annum by 2030

A new report estimates India will reach annual green hydrogen demand of 2.85 million metric tons (MMT) by 2030 under the current policy and project momentum. To meet this demand, it will need 62 GW of additional renewable energy capacity, 29 GW of electrolyzer capacity, and 11 MMT per annum of ammonia infrastructure, which together represent an investment opportunity of at least $57 billion.

Swiss team sets record solar-to-hydrogen rate

Researchers from Switzerland’s École Polytechnique Fédérale de Lausanne have unveiled a new solar dish plant design, while Plug Power has delivered its first electrolyzer system to Europe.

ACME Group, Indraprastha Gas Ltd sign green hydrogen agreement

ACME and Indraprastha Gas Ltd (IGL) have agreed to jointly explore the setting up of hydrogen generation plants, including electrolyzers, to blend green hydrogen in IGL’s natural gas supply.