Central Electronics tenders for solar cells and modules

State-owned engineer Central Electronics Limited has opened tenders to supply 300,000 multi-crystalline cells, with a minimum rating of 4.57 Wp, and 15 MWp of 72-cell, 315 Wp modules.

Stable outlook for operating solar projects, new PV at risk

Solar projects under construction face uncertainty as factors like labour shortage and proposed duties on module imports could lead to significant cost overruns for the developers.

Industry leaders pledge near-zero emissions by 2050

Heavy industry players Dalmia Cement (Bharat) and Hindalco are among the companies committed to enhancing energy efficiency, renewable energy, and circular economy across their member companies and supply chains. Other signatories included Siemens Energy India, Thermax, Shell Group of Companies India and Tata Consulting Engineers.

MNRE invites EoI for installation of innovative solar pumps

The innovators will be required to showcase their technologies in real field conditions. The shortlisted ones will be empanelled and allocated sites to install solar pumps under the Pradhan Mantri Kisan Urja Suraksha evem Utthan Mahabhiyan (PM KUSUM) Scheme.

Solar modules sought for NTPC’s Solapur project in Maharashtra

Domestic manufacturers have until October 27 to bid for the supply of crystalline solar modules aggregating to a nominal DC capacity of 33.6 MWp.

Government to fund innovations in solar and battery storage waste management

The Department of Science & Technology (DST) under India’s Ministry Of Science & Technology seeks to fund promising R&D projects in solar panel and battery storage waste disposal and recycling. Call for proposals closes on November 15.

Thin-film agrivoltaic solar tubes

German tech company Tube Solar AG has secured €10.8 million to develop its cylindrical agrivoltaic modules. The lightweight devices could also be used on roofs until now considered unsuitable for PV.

Rajasthan could add 22.6 GW of new renewable energy capacity to the grid within a decade

The state—which has already installed an aggregate 9.6 GW of renewable energy capacity as of FY 2019-20 end—will add another 22.6 GW to the grid by the end of FY2029-30. Of the new RE addition, 18 GW will come from solar capacity.

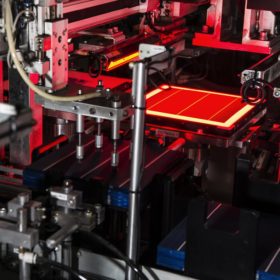

Solar leaders call for overhaul to navigate Covid-19

Faced with raw material and labor shortages, solar manufacturers have stressed the need to find alternative supply chains and to push automation and internet of things applications on the factory floor to keep production running.

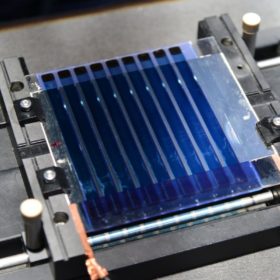

More efficient large-area organic solar cells with spin coating

Researchers in South Korea have used the process to increase performance and the replicability of large-area organic cells. The method was used during film formation to speed up solvent evaporation.