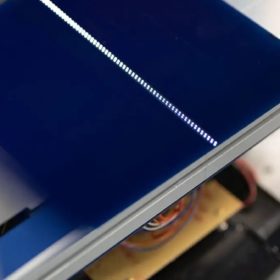

P-type solar products may be phased out by 2026 as n-type tech ‘rapidly’ expands

The rise of cost-effective TOPCon cell technology last year led to a ‘surge’ in production demand for solar n-type cell technology, with leading industry analysts TrendForce prophesying PERC cell capacities ‘may’ be phased out in two to three years. The company’s experts, however, warn that oversupply for p-type cells and modules may increase the price gap between n-type and p-type products in the upcoming months.

ABB to power Samskip’s new hydrogen-fueled container vessels

ABB has secured a complete power, propulsion, and automation systems order for Samskip Group’s hydrogen-powered container vessels. Built by Cochin Shipyard Ltd, the largest shipbuilding and maintenance facility in India, these vessels are among the first in the world to demonstrate the potential of hydrogen fuel cells as a clean and renewable fuel source.

Enabling India’s self-reliance in lithium battery-grade materials

Attero Recycling, India’s largest e-waste and lithium-ion battery recycler, recently processed samples from the Jammu and Kashmir mining belt and was able to recover 200 PPM (parts per million) of lithium carbonate, which was close to the ballpark range shared by the government of India. Nitin Gupta, chief executive officer and co-founder of Attero Recycling, speaks to pv magazine about the significance of their extraction and refining methods in ensuring India’s self-reliance in critical battery-grade materials.

OGO Energy partners Singapore’s noco-noco on battery separator technology

OGO Energy will manufacture battery packs incorporating its battery management system and battery cells with improved longevity and heat-resistance made possible by noco-noco’s X-SEPA separators.

Enapter introduces new electrolyzer

Enapter has unveiled its new AEM Flex 120 electrolyzer, which is designed to expedite the deployment of hydrogen projects in the industrial and refueling sectors, with a daily production capacity of approximately 53 kg.

The Hydrogen Stream: World’s first green hydrogen plant to heat steel

Hitachi Energy has delivered a modular solution to electrify a 20 MW electrolyzer to produce hydrogen to heat steel before rolling, while Enapter has unveiled its AEM electrolyzers for industrial and refuelling pilot projects.

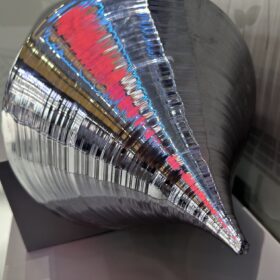

Indian scientists making high-purity polysilicon ingots from recyled PV cells

Indian scientists have produced high-purity polysilicon ingots from recycled solar cells using “spark plasma sintering” (SPS), and claim they may achieve a purity level comparable to commercially available products.

Gautam Solar granted patent for innovation in PV module production

Gautam Solar claims its bussing tool reduces manual work by over 50% and doubles solar panel yield, at a fraction of the cost of an automatic machine.

UK firm to supply argon recycling technology to 2 GW Mundra solar facility

Surrey-based Gas Recovery and Recycle Ltd (GR2L) will supply its ArgonØ machinery that can recycle up to 95% of argon used in the fabrication of silicon wafers for solar panels.

Researchers claim PV near railway tracks is technically feasible

Despite soiling and mechanical stress, PV deployed between or close to rail tracks is not just a crazy idea, states a Bangladeshi-Australian research group. The scientists conducted a techno-economic analysis on a 128 kW demonstrator and found it may achieve a levelized cost of energy of only $0.052/kWh.