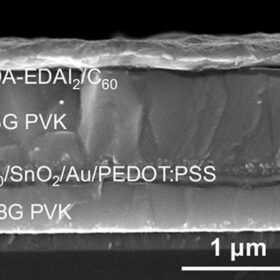

All-perovskite tandem solar cell based on tin-lead perovskite achieves 28.8% efficiency

Conceived by Chinese scientists, the cell was built with new surface reconstruction strategy based on the use of 1,4-butanediamine (BDA) and ethylenediammonium diiodide (EDAI2) as surface modifiers. The device was able to retain 79.7% of its initial efficiency after 550 h.

Oxford PV unveils 26.9% perovskite tandem module efficiency record

Oxford PV has announced a record-setting 26.9% efficiency for its perovskite tandem module at Intersolar Europe 2024, the continent’s largest solar and energy storage event.

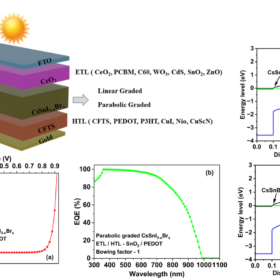

Indian scientists design lead-free perovskite solar cell with 23.61% efficiency

Developed through bandgap engineering and material design, the proposed PV device relies on a tin-based perovskite material known as CsSnI3-xBrx. It can reportedly be further designed to achieve power conversion efficiencies exceeding 24%.

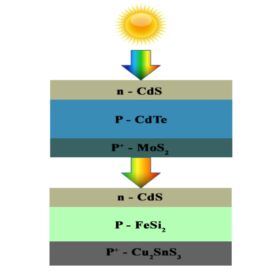

Tandem solar cell based on cadmium telluride, iron disilicide promises 43.9% efficiency

Researchers in Bangladesh have designed a dual-junction tandem solar cell with a bottom device based on iron disilicide (FeSi2), an emerging absorber material know for its high thermal stability and good optoelectronic properties. Their simulation showed the advantage of combining the larger bandgap of the top cadmium telluride cell and the smaller bandgap of the bottom FeSi2 cell.

Perovskite thin film: Out with the old, in with the new

Silicon-perovskite tandem solar requires optimization of both approaches, and embodies the weaknesses of each. Meanwhile, the use of pure thin-film devices offers a cheaper, simpler, and more sustainable PV solution for the United States.

New tech to remanufacture recycled perovskite solar cells

An international research team has developed a novel way to remanufacture fully encapsulated perovskite solar cells after recycling. The researchers say the devices can achieve 88% of the original efficiency of the products.

Perovskite: The next breakthrough in solar panel technology for India

Perovskite technology, with its potential for large-scale deployment and local production, presents a compelling pathway towards a more secure and sustainable energy future.

Canadian startup offers 35%-efficient indoor perovskite PV modules

Canada’s Solaires Entreprises says its indoor perovskite modules are suitable for powering a range of electronic devices, such as wireless keyboards, smart door locks, electronic shelf labels, and sensors.

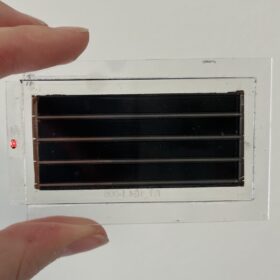

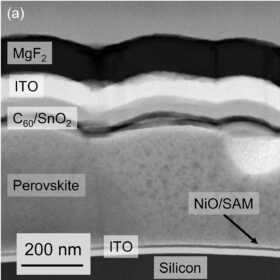

Monolithic perovskite-PERC tandem solar cell with 23.7% efficiency

Dutch scientists have developed a perovskite-PERC tandem solar cell based on a new type of tunnel recombination junction that reportedly offers an improved device efficiency distribution. The cell uses a nickel(II) oxide layer that is intended to reduce electrical shunts in the perovskite top cell.

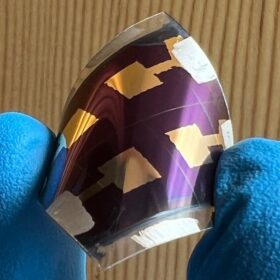

Flexible indoor perovskite solar cell achieves 32.5% efficiency

Italian scientists have developed a flexible indoor perovskite solar cell with 32.5% efficiency. Their design uses a PET substrate combined with a tetrabutylammonium bromide layer over the perovskite absorber. This additional layer effectively reduces defect density and enhances the stability of the underlying 3D perovskite structure.