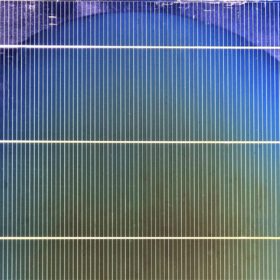

Evaluating the performance of mono- and poly-Si solar PV technologies in Eastern India

Researchers from the SRM Institute of Science and Technology, Ghaziabad, have studied the performance of monocrystalline silicon (mono-Si) and polycrystalline silicon (poly-Si) technologies in the tropical wet region of eastern India. The results showed that the yield outcome with mono-Si PV was around 12% higher and the losses around 32% lower than poly-Si PV.

Indian scientists making high-purity polysilicon ingots from recyled PV cells

Indian scientists have produced high-purity polysilicon ingots from recycled solar cells using “spark plasma sintering” (SPS), and claim they may achieve a purity level comparable to commercially available products.

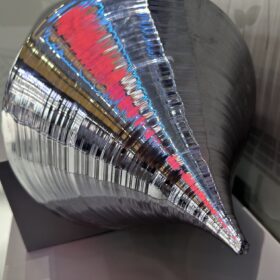

HHV builds directional solidification furnace for solar PV industry

Bengaluru-based Hind High Vacuum (HHV) has designed and built a directional solidification (DSS) furnace to produce polycrystalline silicon ingots in the solar industry.

Fraunhofer ISE develops direct metallization tech for heterojunction solar cells

Germany’s Fraunhofer ISE is applying its FlexTrail-printing technology to the direct metallization of silicon heterojunction solar cells. It said the technique reduces the use of silver, while maintaining high efficiency levels.

Emmvee eyes early-mover advantage with wafer-to-module production

Bengaluru-based Emmvee Photovoltaic has a 1.25 GW module manufacturing facility that can produce polycrystalline and mono PERC solar panels, with the ability to upgrade to TOPCon. By the end of 2023, it will raise its module capacity to 3 GW by adding new units, including 1.5 GW of wafer-to-module capacity. Suhas Donthi, director-sales and operations, spoke to pv magazine about current demand for Indian manufacturers and what’s in store.

REIL seeks 200,000 silicon solar cells

Bids are invited from Indian manufacturers to supply five-busbar mono-/multi-crystalline silicon solar cells rated for minimum of 4.62 watts. Bidding closes on January 27.

Simplifying solar cell deposition

Scientists in Germany have developed a new process for deposition of silicon dioxide layers during cell production. Without the need for high pressure, flammable gases, or vacuum conditions, the process could lead to cost reductions for cell manufacturers, provided it can be developed and applied in a large-scale production setting.

REIL seeks 150,000 multi-crystalline silicon solar cells

Bids are invited from Indian manufacturers to supply four-/five-busbar multi-crystalline silicon solar cells rated for 4.5W peak output. Bidding closes on March 15.

IIT Bombay, BHEL in race to develop high-efficiency solar cells

India’s Ministry of New and Renewable Energy is funding the research to develop high-efficiency crystalline silicon solar cells, including those with passivated emitter and rear contact structure, and perovskites.

REIL seeks two lakh multi-crystalline silicon solar cells, again

Manufacturers have until December 22 to bid for supplying 200,000 four-/five-busbar solar cells rated for a power output of 4.5 watts.