Lithium-iron phosphate prismatic battery cells with energy density of 138 Wh/kg

Chinese energy storage company Imren Battery has introduced its new EVE LF105 lithium-iron phosphate (LFP) prismatic battery cells, which can be used in a wide range of applications, including EVs, renewable energy storage, and other applications.

US solar installers list Qcells, Enphase as top brands

An industry survey led by SolarReviews and NABCEP found two-thirds of solar installers expect high electricity prices to drive demand.

PV manufacturing capacity hit 600 GW in 2022

The new edition of the International Technology Roadmap for Photovoltaic (ITRPV), published this week, finds that 295 GW of PV modules was shipped in 2022, and that prices for silicon PV modules fell by 7% over the year. The report finds that price premiums for n-type modules are now marginal, and the technology grew to represent 15% of the market, and is expected to keep growing over the coming decade.

The PV scientific community’s rush to the latest efficiency record

Perovskite-silicon tandem technology expert Gianluca Coletti explains what cycles the PV industry and scientific community experience every time there are new jumps in power conversion efficiencies at cell level. According to him, we are experiencing a much faster turnover of efficiency records typical of the early stage of development of a new technology holding an incredible potential.

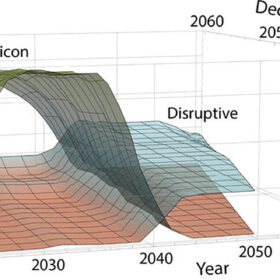

The world can manufacture enough solar to reach decarbonization goals

NREL researchers model viable pathways to supplying the estimated 60 TW of capacity required for decarbonization, and study the effect that disruptive solar technologies may have on deployment cost and market opportunity.

Swiss team sets record solar-to-hydrogen rate

Researchers from Switzerland’s École Polytechnique Fédérale de Lausanne have unveiled a new solar dish plant design, while Plug Power has delivered its first electrolyzer system to Europe.

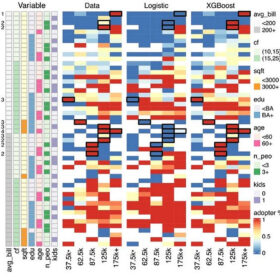

Machine learning method to identify residential PV adopters, reduce soft costs

Researchers have defined a new machine learning-based methodology that reportedly reduces customer acquisition costs by about 15% or $0.07/Watt. It is based on an adapted version of the XGBoost algorithm and considers factors such as summer bills, household income, and homeowner’s age, among others.

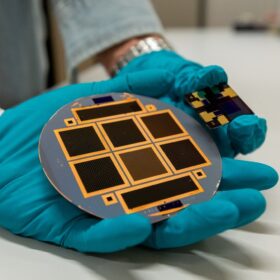

Toyota uses Kaneka’s 26.63%-efficient solar cells for electric vehicle

Kaneka said the cells will be utilized in the roof glass of Toyota’s Prius PHEV electric car. It plans to begin full-scale delivery of in-vehicle PV products this year.

IIT Kanpur, Lohum collaborate on lithium battery testing for safety and sustainability

IIT Kanpur and Lohum will work together to advance lithium-ion battery testing technology and techniques for evaluating battery raw material quality. Lohum will additionally sponsor R&D labs at IIT Kanpur, provide a research fellowship to Ph.D. students, and help IITK commercialize its research outcomes.

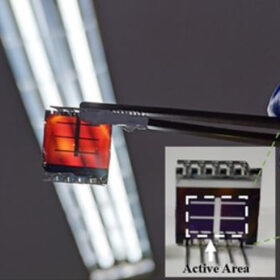

4T silicon-perovskite PV cell hits 26.03% efficiency with transparent contact

Indian scientists have built a four-terminal silicon-perovskite solar cell that uses a top perovskite device with an efficiency of up to 17.1%. The top cell incorporates a room-temperature sputtered transparent conducting electrode (TCE) as a rear electrode.