Risen showcases n-type solar panel with output of 700 W

The 210 mm module can reach a power output of up to 703.6 W and a power conversion efficiency of 23.08%. The result was confirmed by Germany’s TÜV SÜD.

Large-scale solar can cool nearby areas

An international team of scientists observed a cooling effect in a large radius around solar arrays. The cooling may have implications for local ecosystem management.

Vietnamese manufacturer unveils PV module for agrivoltaics

Vietnamese manufacturer Irex has announced a new glass-glass solar panel with a power output of 265 W and a power conversion efficiency of 18.1%.

Silicon metal and aluminum industries hit by China power shortages

A combination of booming demand for coal-fired power and a shortage of the black stuff – exacerbated by a political row with Australia – have forced up prices to the extent fossil fuel generators are making a loss on every unit of electricity they produce. pv magazine‘s Vincent Shaw considers the potential solutions.

Panasonic launches 5 kW fuel cell system for commercial applications

The system has dimensions of 834×417×1,766 mm and weighs 205 kg including the design panel. It achieves an electrical efficiency of 56% and can be connected with a hot water storage unit.

Solar tile with 14.2% efficiency from Denmark

Dansk Solenergi ApS has developed a 13.6 kg tile that can be used for both new buildings and building renovation. The device is currently being produced in Denmark, where the company operates a 40 MW line.

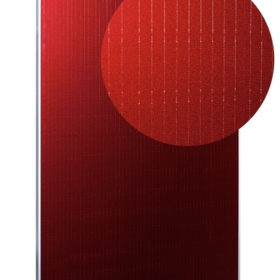

Red BIPV solar module from Italy

The module is available with wattages of 230-245 W and can reach an efficiency of up to 13.45%. The panel is part of a new series of colored products that includes silver and orange modules.

Renewables vs. Nuclear: 256-0

The latest World Nuclear Industry Status Report shows that the world’s operational nuclear capacity grew by just 400 MW in 2020, with generation falling by 4%. By contrast, renewables grew by 256 GW and clean energy production rose by 13%. “Nuclear power is irrelevant in today’s electricity capacity market,” the report’s main author, Mycle Schneider, told pv magazine.

Developer calls world’s largest solar+storage project ‘the first of many’ to come

The Australian-Singaporean group behind a proposed 20 GW solar PV farm and 42 GWh battery energy storage project under development in Australia’s remote far north has hinted that other, similar-sized projects are already in the pipeline.

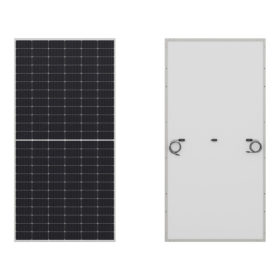

Sharp launches 540 W half-cut PV module with 20.9% efficiency

The IEC/EN61215 and IEC/EN61730-certified panel features 144 half-cells based on M10 wafers and a 10-busbar design. Its operating temperature coefficient is -0.341% per degree Celsius and its power tolerance reaches up to 5%.