Mitigating risks in new PV technologies

The solar energy industry continues to push the boundaries of efficiency and reliability. However, as innovative photovoltaic cell and module technologies emerge, they also bring a new set of challenges in durability and performance. A new report from IEA PVPS Task 13, titled “Degradation and Failure Modes in New Photovoltaic Cell and Module Technologies,” offers a comprehensive analysis of degradation and failure mechanisms in current photovoltaic technologies.

Putting bifacial modules to the test

US scientists recently put different bifacial solar cells and modules through a series of tests at elevated temperature, humidity, voltage and mechanical stress levels. The tests revealed a range of light-induced and potential-induced degradation mechanisms that modules will likely suffer in the field.

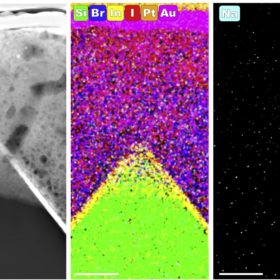

Solar perovskite tandems and potential-induced degradation

Scientists have found that perovskite solar cells and perovskite-silicon tandems might be vulnerable to potential-induced degradation. They exposed tandem cell devices to PID stress and found that they lost as much as 50% of their initial performance after just one day.

How long do rooftop residential solar panels last?

Multiple factors affect the productive lifespan of a residential solar panel. In the first part of this series, we look at the solar panels themselves.

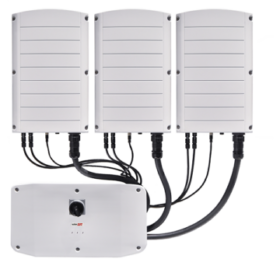

Israel’s SolarEdge launches expanded line of commercial inverters

SolarEdge’s new three-phase inverters are available in variants up to 120 kW, with integrated monitoring and a modular design.

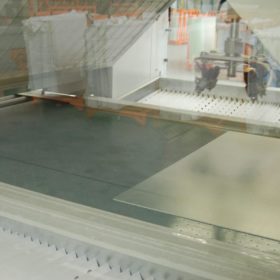

Anti-soiling nanocoating for large-scale PV

Dutch company Rads Global Business has developed an anti-soiling coating for solar PV modules that is claimed to reduce cleaning cost by around 60%. The anti-reflective and anti-corrosive coating is also said to mitigate potential-induced degradation (PID).

Vikram Solar ranked ‘Top Performer’ module manufacturer again

The Kolkata-based manufacturer’s Somera monocrystalline silicon and Eldora polycrystalline silicon PV modules met and exceeded international quality and performance benchmarks in assessments by PV Evolution Labs.

Problems observed in solar module mounting structures in India

Findings from solar installation sites in Gujarat and Rajasthan and some suggestions to handle the issues.

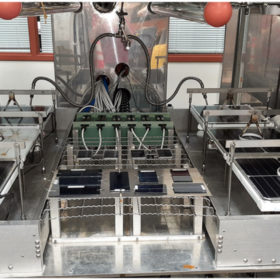

Preventing PID at 1500 volts

Scientists in Germany have developed a “heavy duty” test to provide insight into the long term effects of potential induced degradation in PV modules. The tests go well beyond those established by IEC standards and seek to guide manufacturers and investors on the best choice of materials – encapsulants in particular – when it comes to long term PID resistance.