The long read: PV backsheets – replace or repair?

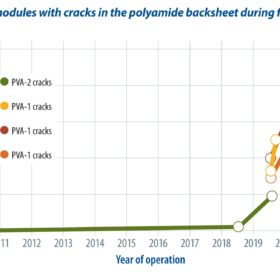

Backsheet chalking, especially of polyamide backsheet films, doesn’t take long to lead to cracks and then safety shutdowns. Sometimes, though, the period may be much longer or shorter than expected. Assessing the risk and whether on-site repairs offer a long-term solution is currently a topic of strong debate within the PV industry, as Cornelia Lichner from the pv magazine Germany team reports.

The long read: New technologies move to the back

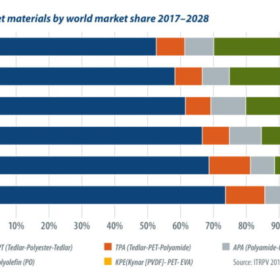

The tension between the cost cutting and performance boosting opportunities presented by new technologies and the tendency for risk aversion is never more evident than in PV module materials. This applies nowhere more than in backsheets, where new innovations are big on promise, but must convince manufacturers and the market of their long-term performance.

The long read: Backsheets to the future

As backsheet manufacturers aim to keep up with cost reductions up and down the PV supply chain, new processes and materials are appearing, with claims to offer better performance as a moisture barrier, as well as better acetic acid permeability and higher reflectivity, among other features. pv magazine examines the state of the market for PV backsheets, and takes a look at some of the new material innovations that are gaining ground with module manufacturers.