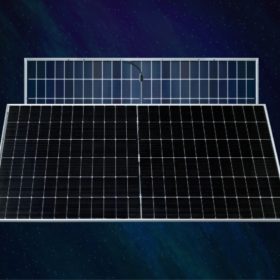

AE Solar unveils n-type TOPCon solar modules with 22.2% efficiency

Germany-based AE Solar said its new panels have a temperature coefficient of -0.35% per degree Celsius and come with a 30-year power output guarantee for 87.4% of the initial yield.

Adani targets 10 GW of polysilicon-to-solar module capacity by 2025

India’s Adani Solar will expand its PV cell and module manufacturing capacity to 10 GW per year by 2025, with backward integration up to the polysilicon stage.

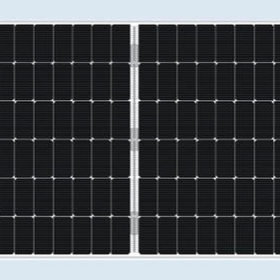

Yingli unveils n-type TOPCon solar panel with 22.0% efficiency

Yingli’s 156-cell Panda 3.0 PRO module has a temperature coefficient of -0.30% per degree Celsius and is available in wattages ranging from 590 W to 615 W, with a bifaciality of more than 90%.

Emmvee eyes early-mover advantage with wafer-to-module production

Bengaluru-based Emmvee Photovoltaic has a 1.25 GW module manufacturing facility that can produce polycrystalline and mono PERC solar panels, with the ability to upgrade to TOPCon. By the end of 2023, it will raise its module capacity to 3 GW by adding new units, including 1.5 GW of wafer-to-module capacity. Suhas Donthi, director-sales and operations, spoke to pv magazine about current demand for Indian manufacturers and what’s in store.

Websol to build 1.8 GW solar cell, module factory

Websol’s board members have approved a proposal to set up a new solar cell and module factory to produce high-efficiency mono-PERC and TopCon products.

Trina Solar achieves 25.5% efficiency in n-type TOPCon solar cell

The result was confirmed by the National Institute of Metrology of China. It was achieved with a cell size of 210x210mm.

POLO-IBC solar cell with 23.7% efficiency

Scientists in Germany have developed two kinds of solar cells based on n-type doped electron-collecting poly-Si on oxide (POLO) junctions with aluminum-alloyed p+ contacts. Both devices are claimed to be possible upgrades of PERC technologies. The best-performant cell is an IBC device showing a power conversion efficiency of 23.71%, an open-circuit voltage of 711.5mV, a short-circuit current of 41.3mA/cm2, and a fill factor of 80.9%.

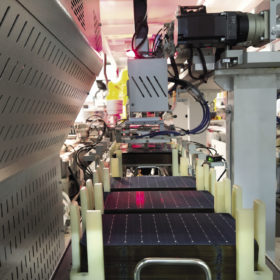

The long read: The right time for TOPCon

The potential advantages of n-type technologies have long been known to solar manufacturers, and such applications have been the focus of much of their research and development activities. Recent developments see 2022 shaping up as the year when n-type goes into mass production, led by tunnel oxide passivated contact (TOPCon) cells. pv magazine takes a closer at this cell technology and its route to the mainstream.

The long read: Expansions in n-type solar tech

The past 12 months have been a turbulent time for PV manufacturing. Rapid and impressive developments in technology have been accompanied by price increases up and down the supply chain, and energy shortages weighed on production in the second half of the year. Chinese n-type module manufacturer Jolywood is now pressing ahead with ambitious expansion plans despite the disruption. pv magazine publisher Eckhart K. Gouras and editor Mark Hutchins recently caught up with Cathy Huang, European sales director at Jolywood, to discuss the company’s plans to bring n-type TOPCon technology into mainstream production.

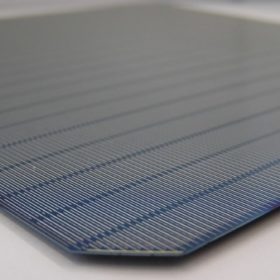

TOPCon vs PERC

TOPCon solar cells are on their way to fully compete with PERC solar products, according to recent research from Germany’s Fraunhofer ISE. Efficiency gains for the TOPCon concept, however, are necessary to help it capture more market share, as production costs remain higher than those for PERC tech. A series of cost-driven strategies to make TOPCon modules advance were outlined in the study.