U.S. decarbonization goals hinge on scaling up heterojunction cell tech

HJT technology could fill an innovation gap in the residential and commercial rooftop PV market, and boost U.S. solar leadership through domestic manufacturing of cells and modules.

The long read: Cloud looms over PV’s silver lining

Should heterojunction solar technologies be temporarily shelved? Could copper plating replace screen-printed silver conductive surfaces in cells? Why are tandem cells a likely successor to PERC? Brett Hallam recently sat down with Natalie Filatoff in Sydney to explain the findings of a new study by UNSW that sought to answer these controversial questions.

Solar module prices will stay high until 2023, IHS Markit says

IHS Markit predicts that global installed solar PV capacity will grow by 20% to over 200 GW in 2022, despite a difficult cost environment. PV system costs are expected to resume their downward trend from 2023, when more polysilicon capacities will come into operation.

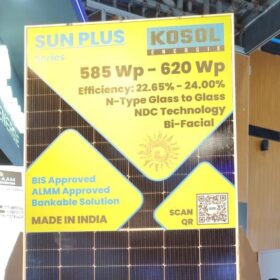

JinkoSolar unveils details of its TopCon 620W bifacial solar panel

The Tiger Neo panel has a power conversion efficiency of up to 22.1% and a temperature coefficient of -0.30% per Celsius degree. The product is made with 182mm wafers, half-cut cells, and has a power output ranging from 590 to 620 W.

JinkoSolar claims 23.53% efficiency for n-type, TOPCon, monocrystalline panel

The PV module relies on Jinko’s TOPCon mono cell technology, for which a record efficiency of 25.25% was announced in late May. TÜV Rheinland has confirmed the result.

All solar cell efficiencies at a glance

The research group led by Professor Martin Green has published Version 58 of the Solar cell efficiency tables. He spoke with pv magazine about the criteria with which these tables are compiled and the importance of result certification by independent third parties.

New Premier solar factory to begin production by April

Indian solar manufacturer Premier Energies is setting up a factory in Telangana with an annual cell and module production capacity of 750 MW. The fab will be equipped to produce large-format panels with wafer sizes up to 210mm.

JinkoSolar claims 24.9% efficiency for n-type monocrystalline cell

The result was confirmed by Germany’s Institute for Solar Energy Research (ISFH).

The long read: Carriers key for quality cell surfaces

The path to lower solar LCOE can be painful; just ask a PV manufacturer. However, ever-larger crystalline wafers may cause more pain than they are worth, argues Gerry Knoch, the managing director of wet bench provider exateq. For high efficiency, eliminating cross contamination in wet processes is vital and can be achieved – with carriers playing an important role.

The long read: Making the connection

Recent years have seen plenty of innovation when it comes to cell interconnection, and the tricks that manufacturers employ to boost output at this stage go well beyond simply adding more busbars, as in many new module concepts, these are forgone entirely. Synergies between cell interconnection and new innovations at other stages will also be key in shaping the modules of the future.